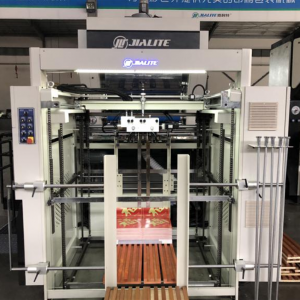

NFM-H1080 Tsis Siv Neeg Ntsug Laminating Tshuab

| Qauv | FM-H |

| FM-1080-Qhov loj tshaj plaws ntawm daim ntawv-hli | 1080 × 1100 |

| FM-1080-Min. daim ntawv loj-hli | 360 × 290 |

| Ceev-m/min | 10-90 |

| Daim ntawv tuab-g/m2 (puag ncig riam txiav) | 80-500 |

| Daim ntawv tuab-g/m2 (slitting riam kub) | ≥115gms |

| Kev sib tshooj precision-mm | ≤ ± 2 |

| Zaj duab xis tuab (micrometer feem ntau) | 10/12/15 |

| Cov kua nplaum tuab-g/m2 | 4-10 |

| Ua ntej-gluing zaj duab xis thickness-g / m2 | 1005,1006,1206 |

| Tsis pub nres qhov siab-hli | 1150 |

| Qhov siab ntawm daim ntawv sau (xws li pallet)-mm | 1050 |

| Phwj chim | 380V-50Hz-3Plub zog cua sov:20Kwlub zog ua haujlwm:35-45KwTag nrho lub zog sawv ntsug:75Kw Lub tshuab hluav taws xob: 160A |

| wkev ua haujlwm siab-Mpa | 15 |

| Lub twj tso kua mis | 80psiLub zog: 3kw |

| Lub tshuab cua | Ntim ntws: 1.0m3 / feeb,Qhov siab ntsuas: 0.8mpaLub zog:5.5kwCov yeeb nkab nqus dejDia.8 hli (xav kom siv lub tshuab cua nruab nrab) |

| Cable tuab-mm2 | 25 |

| Qhov hnyav | 9800kgs |

| Qhov Loj (layout) | 8400 * 2630 * 3000mm |

| Thauj khoom | 40HQ |

Chav pub mis

1. Servo Motor Feeder, 4 lub suckers rau kev tsa thiab 4 lub suckers rau kev xa cov qauv. Max Speed 12000 daim ntawv / teev.

2. Lub rooj noj ntawv muaj kev tiv thaiv sab saud thiab sab qis dua.

3. Qhov siab ntawm kev pub mis tsis tu ncua tuaj yeem ncav cuag 1150mm, cov khoom siv ua ntej stacking, kev pub mis tsis tu ncua.

4. Kev hloov kho ntse ntawm pem hauv ntej thiab nram qab ntawm Feeder, tsuas yog cov ntaub ntawv khoom sau rau ntawm lub vaj huam sib luag tswj hwm

5. BECKER LUB TWJ NTAU NPAUM

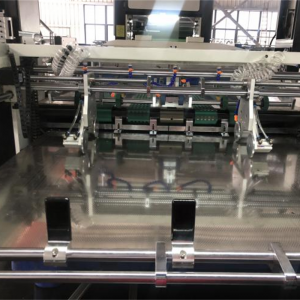

Rooj thauj khoom thiab sib tshooj

1. Lub rooj xa khoom siv tau txais kev cai stainless hlau corrugated board.

2. Lub log txhuam thiab lub log roj hmab txav mus zoo.

3. Servo lub cev muaj zog sib tshooj, txhim kho qhov tseeb ntawm lub lap, qhov yuam kev ≤ ± 2 hli.

TSHUAJ TSHEM Plua Plav THIAB LUB QHOB LAMINATING (XAIV TAU) TSHUAJ TSHEM POWDER LUB QHOB LAMINATE THIAB LUB ZAUB HUVCOV

Ib lub tshuab cua sov rau cov hmoov tshem tawm (xaiv tau) muaj cov qauv me me, lub platform muaj lub luag haujlwm nqus kom ntseeg tau tias daim ntawv los ntawm cov hmoov tshem tawm cov khoom siv tsis txav.

Cov tshuaj tshem plua plav tuaj yeem tshem tawm cov plua plav ntawm qhov chaw ntawm daim ntawv tom qab luam ntawv kom tsis txhob muaj cov pob dawb tom qab daim ntawv tau coated.

Raws li cov neeg siv khoom xav tau nruab inkjet ntaus ntawv rau ntawm lub rooj tshem plua plav, inkjet thiab lamination tshuab tau pom los ntawm ib lub tshuab.

Lub rooj inkjet kuj tseem tuaj yeem xaiv tau ntawm nws tus kheej.

Txheej qhov rai (xaiv tau), muaj lub tshuab nplaum thiab lub qhov cub infrared. Tom qab daim ntawv nplaum lawm, nws yuav lo rau zaj duab xis tom qab dhau los ntawm lub qhov cub infrared.

Chav ziab nrog 12 pcs IR teeb, Tag nrho cov cua sov zog 14.4kw.

Thaum tsis siv cov khoom siv qhov rai, qhov no siv tau ua lub cuab yeej tshem cov hmoov dej.

TUS NEEG UA HAUJ LWM HAUV LUB LAMINATOR

Lub tshuab ziab khaub ncaws txoj kab uas hla tau nce mus txog 1000 hli, siv lub tshuab cua sov electromagnetic.

Lub tshuab cua sov nias siv lub kaw lus cua sov segmented, ua haujlwm tau zoo thiab txuag hluav taws xob.

Max siab ntawm cov menyuam xovxwm yog 12T.

Cov menyuam nplaum thiab cov menyuam ntsuas yog tsav los ntawm ob lub cev muaj zog ywj pheej, ua rau kev hloov kho yooj yim dua.

Cov txheej txheem nplaum Teflon txheej txheem kho, yooj yim los ntxuav thiab tsis nplaum.

Cov khoom siv winding zaj duab xis pov tseg.

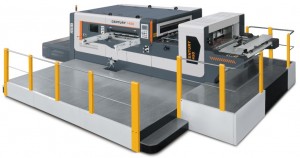

CHAW TXIAV

Lub tshuab txiav ntawv muaj lub tshuab tswj kev nruj thiab lub cuab yeej tiv thaiv kev nkhaus kom ntseeg tau tias daim ntawv tiaj tus thiab tsis nkhaus.

Qhov txiav ntawv muaj lub log sib tsoo, riam disc thiab riam kub rau kev txiav, ua tau raws li cov neeg siv khoom xav tau rau kev txiav cov yeeb yaj kiab ntawm cov ntaub ntawv sib txawv.

Lub tshuab dov bounce roller yog tswj los ntawm lub cev muaj zog ywj pheej, thiab daim ntawv tuaj yeem sib cais los ntawm kev siv qhov sib txawv ntawm qhov ceev.

Riam kub kub tsis tshua muaj siab ncaj qha cua sov thiab txiav tsis muaj zaj duab xis tom qab, ntes tau daim ntawv tuab thiab txiav, raug thiab ua haujlwm tau zoo.

TUS NEEG SAU KHOOM TSIS TXHOB

Qhov siab ntawm lub tshuab sau ntawv uas tsis nres tuaj yeem ncav cuag 1050 hli. Thaum lub pawg ntawv yuav luag puv, txoj siv thauj khoom yuav txuas ntxiv mus txais daim ntawv. Lub platform sau ntawv yuav poob. Tom qab lub tais raug hloov, lub platform yuav rov ua dua tshiab thiab ua tiav lub tshuab sau ntawv uas tsis nres.

Txais yuav cov qauv pneumatic sorting paper sorting los xyuas kom meej tias daim ntawv huv si thiab pab txhawb cov txheej txheem tom ntej, nrog lub log txo qis kom tiv thaiv daim ntawv kom tsis txhob raug puas tsuaj vim yog ntaus lub baffle sai dhau.

Suav lub qhov muag hluav taws xob, tus lej ntawm cov ntawv khiav tau tso tawm ntawm lub vijtsam zaub ntawm lub tshuab nqa, uas tuaj yeem tshem tawm thiab khaws cia.

Lub qhov muag hluav taws xob induction, sensing qhov ntev ntawm daim ntawv, yog tias qhov ntev ntawm daim ntawv hloov pauv, txoj siv yuav ua kom nrawm dua, thiab lub baffle ntawm lub tshuab nqa-up yuav tig thiab tsa daim ntawv.

Tus nqa zaj duab xis

Cov khoom seem