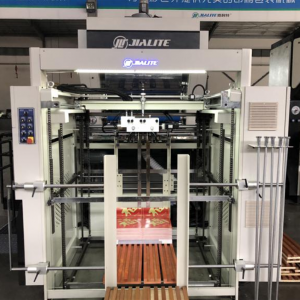

Injin Laminating na atomatik NFM-H1080

| Samfuri | FM-H |

| FM-1080-Matsakaicin girman takarda-mm | 1080×1100 |

| FM-1080-min. girman takarda-mm | 360×290 |

| Gudun-m/min | 10-90 |

| Kauri na takarda-g/m2 (yanka wuka zagaye) | 80-500 |

| Kauri na takarda-g/m2 (rage wuka mai zafi) | ≥115gms |

| Daidaiton haɗuwa-mm | ≤±2 |

| Kauri a fim (micrometer na yau da kullun) | 10/12/15 |

| Kauri manne gama gari-g/m2 | 4-10 |

| Kauri kafin a manne fim ɗin-g/m2 | 1005,1006,1206 |

| Ciyarwa ba tare da tsayawa ba tsayin-mm | 1150 |

| Tsawon takardar mai tarawa (har da faletin)-mm | 1050 |

| Pmai biya | 380V-50Hz-3Pwutar dumama:20Kwƙarfin aiki:35-45KwJimlar ƙarfin lantarki:75Kw Mai warware da'ira: 160A |

| wmatsin lamba-Mpa | 15 |

| famfon injin tsotsa | 80psiƘarfi: 3kw |

| na'urar damfara ta iska | Gudun girma: 1.0m3/min,Matsi mai ƙima: 0.8mpaƘarfi:5.5kwBututun shigaDia.8mm (shawarar amfani da tushen iska mai tsakiya) |

| Kauri na kebul-mm2 | 25 |

| Nauyi | 9800kgs |

| Girma (shiri) | 8400*2630*3000mm |

| Ana lodawa | 40HQ |

RAKON CIYARWA

1. Na'urar ciyar da injin Servo, na'urorin tsotsa guda 4 don ɗagawa da na'urorin tsotsa guda 4 don jigilar kaya. Matsakaicin gudu: zanen gado 12000 a kowace awa.

2. Teburin ciyar da takarda yana da kariya daga sama da ƙasa daga wuce gona da iri.

3. Tsawon ciyarwa ba tare da tsayawa ba zai iya kaiwa 1150mm, na'urar da ke ajiyewa kafin ta yi tsayi, ciyarwa ba tare da tsayawa ba.

4. Daidaita hankali na matsayi na gaba da na baya na Feeder, kawai shigar da bayanan samfuri akan kwamitin sarrafawa

5. FAMFO MAI RUWAN BECKER

JIRA DA JUYA TEBURIN

1. Teburin jigilar kaya yana amfani da allon ƙarfe na musamman.

2. Tayar goga da tayar matse roba suna tafiya cikin sauƙi.

3. Motar Servo ta haɗu, inganta daidaiton cinya, kuskure ≤±2mm.

CIRE ƘURA DA LAMINATING NA TAGO (ZABI) Mai rufe taga da na'urar busar da podwer

Na'urar cire foda mai dumama guda ɗaya (zaɓi ne) tana da tsari mai ƙanƙanta, dandamalin yana da aikin tsotsa don tabbatar da cewa na'urar cire takarda ta hanyar foda ba ta canzawa.

Na'urar cire ƙura za ta iya cire ƙurar da ke saman takardar bayan an buga ta don guje wa fararen tabo bayan an shafa mata fenti.

Dangane da buƙatun abokin ciniki, shigar da na'urar inkjet akan teburin cire ƙura, inkjet da injin laminating ana aiwatar da su ta hanyar injin guda ɗaya.

Ana iya zaɓar teburin inkjet daban-daban.

Rufin taga (zaɓi ne), wanda aka yi da kan injin mannewa da tanda mai infrared. Bayan an manne takardar, ana haɗa ta da fim ɗin bayan an ratsa ta cikin tanda mai infrared.

Na'urar busarwa da hasken IR guda 12, Jimlar ƙarfin dumama 14.4kw.

Lokacin da ba a amfani da kayayyakin taga ba, ana iya amfani da wannan ɓangaren azaman na'urar cire foda na ruwa.

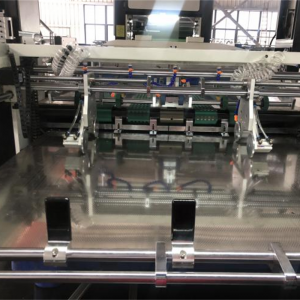

Mai watsa shiri na Laminator

Girman busar da nadi ya karu zuwa 1000mm, ta amfani da tsarin dumama lantarki.

Na'urar dumama ta na'urar ta yi amfani da tsarin dumama mai sassa daban-daban, mai inganci kuma mai adana makamashi.

Matsakaicin matsin lamba na abin nadi na latsa shine 12T.

Injinan da ke amfani da manne da na'urar aunawa suna aiki ta hanyar injinan da ba su da alaƙa da juna biyu, wanda hakan ke sa daidaitawa ya fi dacewa.

Tsarin mannewa na Teflon, mai sauƙin tsaftacewa kuma ba ya mannewa.

Na'urar murɗa fim ɗin sharar gida.

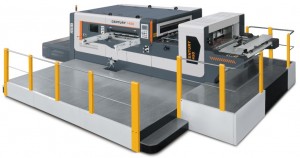

RUKUNIN YANKA

An sanya na'urar yanke takarda da na'urar sarrafa matsin lamba da kuma na'urar hana lanƙwasa don tabbatar da cewa takardar ba ta lanƙwasa ba.

Sashen yanke takarda ya ƙunshi keken niƙa, wukar diski da kuma wuka mai zafi don yankewa, wanda ke biyan buƙatun abokan ciniki na yanke fina-finai na kayan aiki daban-daban.

Ana sarrafa na'urar billa ta hanyar injin mai zaman kansa, kuma ana iya raba takardar ta hanyar amfani da bambancin gudu.

Wuka mai zafi mai ƙarancin matsin lamba da yankewa kai tsaye ba tare da fim ɗin wutsiya ba, gano kauri da yanke takarda, daidai kuma mai inganci.

MAI TARIN HANYAR BAN TSAYEWA

Tsawon mai tattarawa mara tsayawa zai iya kaiwa 1050mm. Idan tarin ya kusa cika, bel ɗin jigilar kaya zai faɗaɗa ta atomatik don karɓar takardar. Dandalin tattarawa zai faɗi. Bayan an maye gurbin tiren, dandamalin zai sake yin amfani da shi kuma ya kammala mai tattarawa mara tsayawa.

Ɗauki tsarin rarraba takarda ta hanyar iska don tabbatar da tsaftar takardar da kuma sauƙaƙe tsari na gaba, tare da dabarar ragewa don hana takardar lalacewa saboda bugun baffle da sauri.

Ana ƙirga idon lantarki, ana nuna adadin takarda mai gudana akan allon nuni a injin ɗaukar kaya, wanda za'a iya sharewa da tattarawa.

Induction electric eye, wanda ke fahimtar tsawon takardar, idan tsawon takardar ya canza, bel ɗin zai yi sauri, kuma baffle na na'urar ɗaukar kaya zai juye ya ɗaga takardar.

Mai ɗaukar fim

Kayayyakin gyara