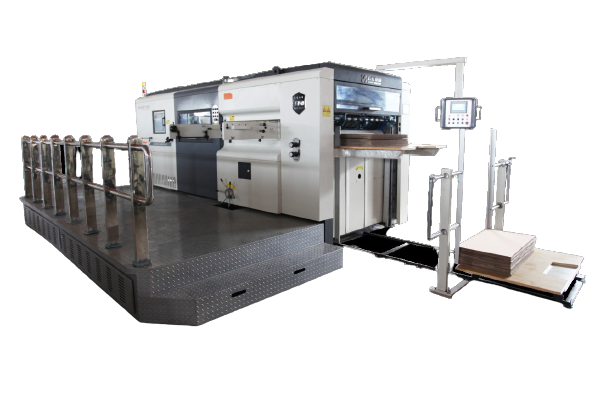

Century MWB 1450Q (tare da yankewa) Mai yanke mutu mai faɗi da aka yi da Semi-Auto

| Samfuri | MWB1450Q |

| Girman Takarda Mafi Girma | 1480*1080 mm |

| Ƙaramin Girman Takarda | 550*480 mm |

| Matsakaicin Girman Yankan | 1450*1050 mm |

| Matsakaicin Matsi na Yankan | 300x104N |

| Nisa Tsakanin Hannun Jari | Allon da aka yi da roba ≤ 9 mm |

| Daidaiton Yanke Mutu | ±0.5 mm |

| Matsakaicin Gudun Inji | 4000s/h |

| Daidaita matsin lamba | ±1 mm |

| Mafi ƙarancin Gefen Gaba | 8MM |

| Girman Bikin Cikin Gida | 1480*1080 mm |

| Jimlar Ƙarfi | 21KW (ban da dandamalin aiki |

| Girman Inji | 7750*4860*2440 mm (Haɗa da dandamalin aiki, mai ciyarwa kafin lokaci) MWB1620Q |

| Girman Inji | 5140*2605*2240 mm (Banda dandamalin aiki, mai ciyarwa kafin lokaci) MWB1620Q |

| Jimlar Nauyi | 19t |

Sashen Ciyarwa

√Tsarin ciyarwa mai inganci da hannu.

√Tsarin ɗaga tari na takarda ta atomatik.

√Jagorar gefe don sanya cibiyar tarin takarda.

√Ya dace da E, B, C, A sarewa da bango biyu.

Sashen Yankan Mutu

√Tsarin kulle maɓallan pneumatic die-chase don tabbatar da aminci da sauƙin canza farantin yankewa na mutu.

√Tsarin layi na tsakiya don saita da canza kayan aikin yankewa cikin sauri.

√Tsarin ƙugiya don matsakaicin matsin lamba na yankewa har zuwa tan 400

√Tsarin man shafawa mai sarrafa kansa ta atomatik da mai zaman kansa don aiki mai santsi da tsawon rai

√Ƙofar tsaro da na'urar daukar hoto don aiki lafiya.

Sashen Yankewa

√Ana iya ɗaga firam ɗin cire kayan da aka saka a sama don cire kayan da aka saka da kuma canza su.

√Tsarin tsakiya don saita na'urar cire kayan aiki cikin sauri da kuma canza aiki

√Na'urar kulle firam, mai sassauƙa kuma mai sauƙin kullewa da sassauta na'urar cire kayan.

√An sanya na'urar daukar hoto da taga mai aminci don aiki lafiya.

√Tsarin cirewa na rabin-rabi yana barin gefen riƙewa bai cire ba.

Sashen Isarwa

√Masu tsalle-tsalle a gefe da gaba domin tabbatar da tsafta.

√Tsarin isar da fale-falen fale-falen

√Na'urar binciken hoto ta lantarki don shiga da aiki cikin aminci.

Sashen Kula da Lantarki

√Siemens PLC fasahar don tabbatar da cewa babu matsala a gudanar da aiki.

√Kayan aikin lantarki daga Siemens, Schneider ne.

√Duk kayan lantarki sun cika ƙa'idar CE

| Sunan wani ɓangare | Alamar kasuwanci |

| Babban hali | NSK |

| Babban sarkar tuƙi | RENOLD |

| Mai Canza Mita | YASKAWA |

| Kayan Wutar Lantarki | Siemens/Schneider |

| Mai Encoder | OMRON |

| Na'urori masu auna hoto | Panasonic/Omron |

| Babban injin | Siemens |

| bangaren iska | AirTac/SMC |

| Kamfanin PLC | Siemens |

| Taɓawa Faifan Shafawa | Siemens |

Mai Ciyarwa Kafin

Wannan na'urar ciyarwa ta farko tana taimakawa wajen shirya zanen gado na gaba da kuma canza zanen gado cikin sauri. Lokacin da mai aiki ke ciyar da zanen gado ga mai yanke zanen gado, wani mai aiki zai iya shirya wani tarin zanen gado a lokaci guda. Da zarar an gama ciyar da zanen gado, ana iya tura tarin zanen gado da aka shirya akan na'urar ciyarwa ta atomatik zuwa na'urar ɗaga tarin takardu ta atomatik. Wannan zai adana kimanin mintuna 5 na shirya tarin zanen gado kowannensu kuma yana ƙara yawan aiki.

Kwamitin aiki tare da hannu mai motsi // Siemens Smart line Touch Panel

Sashen Ciyarwa

√Kyamara don sa ido kan yanayin sashen isar da kaya a ciki

√ Tsarin ɗaga tari ta atomatik

√Na'urar daidaita gibin da ke tsakanin zanen gado da maƙallan riƙewa.

√Tagar tsaro da na'urar firikwensin hoto suna ba da kariya ga mai aiki da injin lokacin da taga tagar tsaro ta buɗe.

√ Danna faranti don tabbatar da cewa zanen gado ba su taɓa cin abinci fiye da kima ba har sai sun mutu

√Motsa jiki a gefen hanya domin kiyaye tarin a tsakiya koyaushe kuma a cimma daidaiton takardar da aka saka a ciki.

Na'urar firikwensin hoto don ci gaba da ɗaga tarin abubuwa koyaushe a lokaci don ciyar da zanen gado.

Sashen Yankan Mutu

√An yi farantin yanke mutu da ƙarfin 65Mn mai tauri kamar HRC45, wanda ya dace da yanke mutu.

√Tagar tsaro an sanya mata don tsaron ma'aikaci da injin.

√ Tsarin layin tsakiya don saita kayan yanka da sauri da kuma canza aiki.

√Mai daidaita ƙarfin yankewa. Mai sauƙi kuma mai sauƙi.

Tayar tsutsa tare da injin niƙa hannu don tabbatar da santsi na saman don yankewa daidai.

Tsarin man shafawa na kai-tsaye ta atomatik

An yi amfani da monocast don rage girgiza lokacin da injin ke aiki.

Ana iya daidaita apron na tallafi zuwa girma dabam-dabam don girman zanen gado daban-daban.

Sashen Isarwa

√ Tsarin isar da fale-falen ba tare da tsayawa ba

√Allon aiki

√Tagar tsaro

√Na'urar firikwensin hoto tana da kayan aiki don tabbatar da cewa na'urar za ta tsaya lokacin da wani abu ya shiga na'urar a wannan sashe.

√Motocin motsa jiki na gefe don tattara zanen gado masu kyau

Tagar kallo don duba tarin takardu kuma yi wasu gyare-gyaren da suka wajaba idan ya cancanta.

Na'urar daidaita tsarin takarda

Sarrafa Wutar Lantarki

Module na CPU // Siemens Simatic S7-200

Mai Canza Mitar Yaskawa

Na'urorin watsawa na Schneider, masu haɗa na'urori da sauransu.

Sandunan gripper, waɗanda aka yi da kayan aikin iskar gas na aluminum.

Za a aika ƙarin saitin sandunan riƙewa guda biyu tare da injin a matsayin kayan gyara.

-300x179.jpg)

-300x204.jpg)

-300x179.jpg)

-300x200.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)