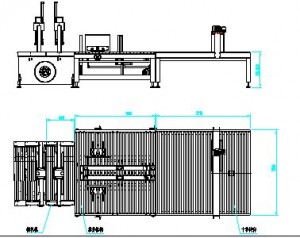

Ukunyathelisa kwe-SAIOB-Vacuum Flexo kanye ne-Slotting kanye nokusika i-Die kanye ne-Glue ku-Line

| Igama | Inani |

| Iyunithi yokudla (i-Lead Edge feeder) | 1 |

| Iyunithi yokuphrinta (i-Ceramic anilox roller + Blade) | 4 |

| Iyunithi yokubeka (umgodi wesikhala esiphindwe kabili) | 1 |

| Iyunithi yokusika idayisi | 1 |

| Iyunithi yokunamathisela okuzenzakalelayo | 1 |

Ukunyathelisa kwe-Flexo nokusika i-SAIOB-Vacuum kanye ne-Slotting kanye ne-die cutting kanye ne-gluer emgqeni

(Ukucushwa kokusebenza kanye namapharamitha obuchwepheshe)

Iyunithi yokusebenza elawulwa yikhompyutha

1. Umshini usebenzisa ukulawulwa kwekhompyutha, ngomshayeli we-servo waseJapan.

2. Iyunithi ngayinye ifakwe isikrini sokuthinta se-HMI esinokusebenza okulula, ukulungiswa okunembile kanye ne-auto zero.

3. Umsebenzi wememori: uma idatha efanele ifakwa, igcinwa ngokuzenzakalelayo ukuze isetshenziswe ngokulandelayo. Umsebenzi wememori we-9999.

4. Idatha ingalungiswa ngayinye, ngaphandle kokusebenzisa umsebenzi we-oda. Umqhubi angasebenzisa ngokuzenzakalelayo idatha yokufaka ezimele esebenzisa uhlelo lokusetha ibhokisi elilodwa. Ubude, ububanzi nokuphakama kwebhokisi kungafakwa futhi iyunithi yesikhala izosethwa ngokuzenzakalelayo.

5. Umshini ungalungiswa ngokuzimela bese idatha entsha ivuselelwa uma uboniswa ivumela opharetha ukuthi abone iphutha emshinini lisebenza.

6. Uhlelo lokusekelayo uma kwenzeka ukulahlekelwa yinkumbulo. Idatha ingabuyiselwa kalula.

7. Uma kwenzeka umshini udinga ukuvulwa ngesikhathi usebenza, lapho uvala umshini uzobuyela ngokuzenzakalelayo endaweni yawo yokuqala.

8. Ukuphakamisa i-anilox ngokuzenzakalelayo ukuze kongiwe ukuhlanza okungadingekile.

9. Isikrini esikhulu semoto sibonisa isivinini, ukudla, ukugijima

10. Isikrini esiyinhloko sibonisa isethi ye-oda, futhi uma kukhiqizwa inombolo yangempela, i-feed iyama ngokuzenzakalelayo bese i-anilox iphakama ngokuzenzakalelayo kusuka epuletini.

11. Izitayela zekhathoni ezisethwe ngaphambilini ziyatholakala.

12. Osayizi bonke baboniswa ngokusobala.

13. Ukuthuthukiswa kwesofthiwe kwamahhala kweminyaka emithathu.

Iyunithi yokudla isebenzisa ubuchwepheshe be-JC lead edge feeder, efanelekile kuzo zonke izinhlobo ze-corrugated.

I-feed roller eqhutshwa ama-servo motors angu-4, ngaphandle kwephutha lokudlulisela ngomshini.

Umfutho womoya we-vacuum ungalungiswa ngokuya ngosayizi wephepha.

Irola yokuphakelwa kwenjoloba engenhla ephindwe kabili enobubanzi obungu-147.6mm

I-roller eqinile ye-chome yensimbi ephansi ephindwe kabili enobubanzi obungu-157.45mm

Ukulungiswa kwenjini okunesibonisi sedijithali (0-12mm)

Ifakwe udoti wokufutha kanye nokususwa kothuli. Lokhu kususa uthuli oluningi endaweni yokuphrinta, ngaleyo ndlela kuthuthukiswe ikhwalithi yokuphrinta.

Ngalesi simiso sokumunca, umonakalo ephepheni eligoqekile uyancishiswa futhi naphezu kwezinguquko ezincane ekujiyeni kwebhodi, ikhwalithi yokuphrinta ayithinteki.

Iyunithi yokuphakelayo ingalungiseka ngokugcwele kokubili ngesandla, nge-motorization kanye nokulawulwa kwekhompyutha ye-CNC.

I-Auto Zero ivumela umshini ukuthi uvuleke, kwenziwe izinguquko, uvalwe bese ubuyiselwa emuva endaweni engu-zero, ngaleyo ndlela kongiwe isikhathi somsebenzisi.

Ububanzi bangaphandle bungu-393.97 (ububanzi bepuleti lokuphrinta bungu-408.37mm)

Ukulungiswa kwebhalansi eqinile neguquguqukayo, ukusebenza kahle.

Umhlabathi ongaphezulu one-chrome plating eqinile.

Ukunamathiselwa kwe-stereo ngohlelo lwe-ratchet olusheshayo.

Isilinda se-stereo singaqhutshwa nge-pedal yonyawo lomqhubi ukuze sisethwe.

1. Ububanzi bangaphandle buyi-172.2mm

2. Ukugaya ubuso bensimbi, i-chrome plating eqinile.

3. Ukulungiswa kwebhalansi kanye nokusebenza okubushelelezi.

4. Ukulungiswa kwe-nip yokuphrinta kusethwe ngokulawulwa kwekhompyutha kanye nedijithali kagesi.

1. Ububanzi bangaphandle bungu-236.18mm.

2. Isisekelo sensimbi esinesembozo se-ceramic.

3. Kuqoshwe nge-laser ngokwezidingo zamakhasimende.

4. Umklamo wokushintsha okusheshayo wokulungisa okulula

1. Ububanzi bangaphandle buyi-211mm

2. Insimbi eboshwe ngerabha evikela ukugqwala

3. Gcwalisa ngomqhele

5. Igumbi elivalwe nge-aluminium elenzelwe ngokukhethekile, elingonga imali efika ku-20% yokuchitha uyinki.

6. Ifakwe ungqimba oluhlaza lwe-PTFE, okulula ukuyihlanza futhi enganamatheli.

7. Ukusetshenziswa kwendlela yokushintsha ngokushesha i-anilox kuyatholakala njengenketho.

1. Igiya leplanethi elinokulungiswa kwamadigri angu-360

2. Indawo eseceleni ingalungiseka ngogesi ngokulawula isikrini sokuthinta se-PLC, ibanga elingama-20mm, kanye nokulungiswa okuncane okufika ku-0.10mm.

3. Ukulungiswa okujikelezayo kwenziwa ngesikrini sokuthinta se-PLC esinokunyakaza okungu-360

4. Ukulungiswa okuncane nge-inverter ukuze kulungiswe kahle kufikela ku-0.10mm

1. Iphampu ye-diaphragm yomoya inikeza ukuzinza kweyinki, ukusebenza okulula kanye nokugcinwa kwayo.

2. Isexwayiso se-inki ephansi.

3. Isihlungi seyinki ukususa ukungcola.

1. Ububanzi bomgodi buyi-154mm, bumbozwe nge-chrome eqinile.

2. Ingcindezi ilungiswa ngogesi kusukela ku-0-12mm futhi iboniswa ngesibonisi sedijithali.

1. Ububanzi bomgodi obuyi-174mm obuqiniswe nge-chrome eqinile.

2. Ububanzi bommese onezimbobo buyi-7mm.

3. Imimese iyinsimbi eqinile, egobile futhi egobile.

4. Ummese wokusika onezicucu ezimbili onembile kakhulu.

5. Isiteshi se-slot sisethwe ngesikrini sokuthinta se-PLC esinememori yama-oda ayi-1000.

Isinxephezelo

1. Isinxephezeli segiya leplanethi, ukulungiswa kokubuyela emuva kwamadigri angu-360.

2. Isigaba sokufaka i-slotting, ukusebenzisa i-PLC yommese ohamba phambili nowangemuva, ukulawula isikrini sokuthinta kanye nokulungiswa kwedijithali kagesi engu-360.

Inketho yokusebenzisa amathuluzi embobo yesandla

1. Ngezinduna ze-aluminium kanye namasethi amabili amathuluzi asikiwe ngodayi (ububanzi obungu-110).

Ingxenye yokomisa ye-infrared (inketho)

1. Iyunithi yokomisa eyisivikelo se-vacuum; idrayivu ye-servo ezimele.

2. Ukudluliselwa okusizayo kwe-vacuum cleaner okugcwele.

3. Ukushisa okungalungiseka ngokosayizi wephepha.

4. Itafula lokudlulisa elikwazi ukuphakamisa.

Iyunithi Yokusika Ngokufa (isethi eyodwa)

Igebe lesilinda esidayiwe kanye ne-anvil lilungiseka ngogesi ngesibonisi sedijithali.

Imisebenzi Yokusebenza

1. Isilinda se-die kanye ne-anvil, uma zingasebenzi, zivulwa ngokuzenzakalelayo ukuze kuncishiswe umthelela emshinini futhi kwandiswe isikhathi sokuphila kwe-urethane.

2. Isilinda sedayi sinokulungiswa okuvundlile okungu-10mm.

3. Isilinda se-Anvil sifakwe isenzo sokuzingela esizenzakalelayo esifinyelela ku-30mm, esisabalala ngokulinganayo lapho futhi sandise impilo.

4. Umshini uhlonyiswe ngokuvumelanisa i-anvil eqhutshwa yi-servo ukusiza ekuthuthukiseni ukunemba ngama-anvil agugile.

Isilinda Esiyindilinga

1. Isilinda sedayi kufanele selulekwe kuye ngesimo

2. Insimbi eyakhiwe nge-alloy enepuleti le-chrome eliqinile.

3. Izimbobo zezikulufo zokulungisa i-die zibekwe kanje: i-axial engu-100mm, i-radial engu-18mm.

4. Ukuphakama kwesikhiphi sedayi 23.8mm.

5. Ubukhulu bokhuni lokusika insimbi: 16mm (ibhodi lephepha elinezingqimba ezintathu)

13mm (ibhodi lephepha elinezingqimba ezinhlanu)

Isilinda se-Anvil

1. Isilinda se-Urethane Anvil

2. Insimbi eyakhiwe nge-alloy enepuleti le-chrome eliqinile.

3. Ubukhulu be-urethane obungu-10mm (ububanzi obungu-457.6mm) Ububanzi obungu-250mm (impilo yokusika eyizigidi ezingu-8)

I-Gluer yefolda

1. Ibhande lokumunca

2. I-inverter eqhutshwa ukulawula ukunemba kwegebe

3. Isivinini esiguquguqukayo sebhande lesobunxele nelesokudla ukuze kube nokunemba okukhulu kokugoqa.

4. Isethi yezimoto ezingalweni

I-Counter Ejector

1. Umklamo wokulayisha ophezulu wokusebenza ngesivinini esiphezulu okubushelelezi kanye nokuphahlazeka okungenalutho lapho usebenza ngaphandle kwe-glue lap noma umsebenzi we-SRP

2. Umjikelezo oqhutshwa yi-Servo

3. Inani elinembile le-batch

Isitimela segiya elikhulu lokudlulisa

1. Sebenzisa insimbi ye-alloy engu-20CrMnTi egayiwe, efakwe i-carburized

2. Ukuqina kwe-HRC 58-62 kunikeza impilo ende (kuze kube yiminyaka eyi-10 ngaphandle kokuguga kakhulu)

3. Ukuxhumeka kwamahhala kokhiye ukuze kube nokunemba kwesikhathi eside

4. Iphampu ye-oil yegiya elikabili ene-spray yamaphuzu amaningi

| Imininingwane | 2500 x 1200 |

| Isivinini esiphezulu (iminithi) | Ishidi elingu-280Inqwaba engu-20 |

| Usayizi Wokudla Okuphezulu (mm) | 2500 x 1170 |

| Usayizi we-Feeder we-Skip (mm) | 2500 x1400 |

| Usayizi Wokudla Omncane (mm) | 650 x 450 |

| Indawo yokuphrinta ephezulu (mm) | 2450 x1120 |

| Ubukhulu be-Stereo(mm) | 7.2mm |

| Amaphaneli (mm) | 140x140x140x140240x80x240x80 |

| Usayizi we-Max Die Cutter (mm) | 2400 x 1120 |

| Ubukhulu beshidi (mm) | 2-10mm |

Inani Lokucaciswa Kwegama

- Injini Eyinhloko (CDQC) 40KW 1

- Irola Yokuhambisa Okuphakelayo engu-0.1KW 1

- I-Forward Roller 0.1KW 1

- Isango Lomphetho (eShayina) 0.12KW 1/30 1

- Ukuhambisa Okuphakelayo (eTaiwan) 0.75KW 1/71 2

- I-Bezel Yesobunxele Nesokudla (eShayina) 0.25KW 1/29 2

- Amafeni (eShayina) 5.5KW 2

Iyunithi Yephrinta

- Ukulungiswa Kwerola Yerabha (eTaiwan) 0.4KW 1

- I-Anilox Lift (eTaiwan) 0.2KW 1

- Ukusebenza kwe-Anilox (eTaiwan) 0.4KW 1

- Ukunyakaza Kweyunithi (eTaiwan) 0.4KW 1

- Ukusebenza kwe-Rubber Roller (eTaiwan) 0.75KW 1

- Ukuguqulwa Kwesigaba (eTaiwan) 0.37KW 1/20 1

- Ithebula Lokuphakamisa (eTaiwan) 0.37KW 1/30 1

- I-Tensile (Taiwan) 0.37KW 1/50 1

- Amafeni (eShayina) 5.5KW 1

Iyunithi ye-Slotter

- Ukuguqulwa Kwesigaba (eShayina) 0.37KW 1/20 2

- Ipuleti Lomhlahlandlela Elinezimbobo (eShayina) 0.55KW 4

- Hambisa iMoto (eTaiwan) 0.4KW 1

- I-Conveyor Roller 0.1KW 2

Iyunithi Yokusika Idayi

- Ukuphakamisa I-Die (eTaiwan) 0.2KW 1

- Imfucuza Yokusika Idayi (eTaiwan) 0.4KW 1

- Ukuguqulwa Kwesigaba (eTaiwan) 0.37KW 1/20 1

- I-Tensile ene-(Taiwan) 0.37KW 1/50 1

- Isibungu Esisikayo (eShayina) 1/100 1

- I-Conveyor Roller (eTaiwan) 0.1KW 1

Iyunithi Yezokuthutha

- Injini Eyinhloko (i-Siemens) 0.75KW 1

- Injini Eseceleni (eTaiwan) 0.4KW 4

- Ingalo Yokukhetha (eTaiwan) 0.4KW 2

- Phansi bese Ususa Injini (eTaiwan) 0.4KW 2

Iyunithi Yokugoqa

- Injini Yesondo Leglue (eTaiwan) 0.4KW 1

- Ukuhambisa Iglue (eTaiwan) 0.4KW 1

- Ifeni Yokuncela (eShayina) 2.2KW 4

- Umlandeli Wephepha (eShayina) 3KW 1

- Injini Yomugqa (eShayina) 0.4KW 2

- Phansi bese Ususa Injini (eTaiwan) 1.5KW 2

- Injini Elawulayo (eTaiwan) 37KW 2

- Injini Yesikhala Sokudlulisa 0.37KW 1

Iyunithi Yokukhipha

- Injini Yokudlulisa Amagiya (eTaiwan) 0.75KW 2

- Injini Yokudlulisa Iphepha (eTaiwan) 1.5KW 2

- I-Baffle Yangemuva (eTaiwan) 0.55KW 1

- Ithebula Lokwamukela (eTaiwan) 0.37KW 1

- I-Baffle Yangemuva (eTaiwan) 0.55KW 1

- Ithebula Lokwamukela (eTaiwan) 0.37KW 1

- Injini Yokuthwala I-Press (eTaiwan) 0.37KW 2

- Injini Ye-Servo Yephepha (eJapan) 3KW 1

- I-Servo Yephepha Elisekelayo 5KW 2

Enye Incazelo

Inani Lomsuka Wegama

- I-Bearing NSK, C&U Konke

- I-Servo Lead Edge Feeder Japan (Omron) Konke

- I-Ceramic Anilox Roller Haili, GuangTai Zonke

- I-AC Contactor, i-Thermal Relay Siemens Konke

- I-PLC Japan (Omron) Konke

- I-Encoder Italy (ELTRA) Konke

- Isikrini Sokuthinta iSweden (Beijer) Konke

- Indandatho Yokuxhumana Yamahhala eShayina Konke

- Iphampu Yoyinki YaseShayina Konke

- I-Inverter Japan (Yaskawa) Konke

- I-Solenoid Valve Taiwan (Airtac) Konke

- Ummese eTaiwan (Jeefeng) Konke

- Isembozo se-Anvil Taiwan (Maxdura) Konke