I-GUOWANG C106 NGOKWENZAKALELAYO NGOKUNGAKHULULI

Ikhanda le-feeder elisezingeni eliphezulu

Uhlelo lomugqa ophakathi

Ukujaha ukufa kokukhiya komoya

Ukondla nokulethwa okunganqamuki

Amashidi angu-7500/H

Ukucindezela okuphezulu.300T

Isikrini sokuthinta esikabili ukuze kube lula ukusebenza

Insimbi yokuphonsa ethambile ye-HT500-7

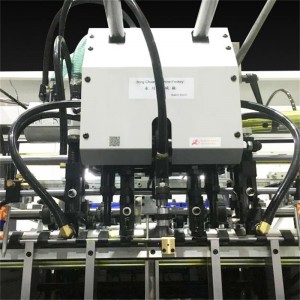

INHLOKO YOKUDLA I-feeder esezingeni eliphezulu, ama-sucker angu-4 kanye nama-forwarder angu-4

I-FEEDER Idivayisi ye-pre-pile, Ukudla okungayeki. Ukuphakama kwe-pile 1600mm

I-Air Pump yaseJalimane i-Becker

ITHEBHULE LOKUDLA Ibhande lokudlulisa i-Nitta Ithebula lokudlulisa i-slope yensimbi engagqwali

ISIGABA SOKUKHUPHA Uhlelo lomugqa ophakathi nendawo Ukuphakamisa ukujaha okuphezulu komoya Ukuhlukanisa ikhamera ukuze ulawule isikhundla sokujaha okuphezulu, okuphakathi, nokuphansi Ikhwalithi yomkhiqizo ephezulu ngokukhumula okuzenzakalelayo

ISIGABA ESIQEDA UKUFA Injini ye-servo evela eJapan FUJI Ingcindezi ingalungiswa esikrinini sokuthinta esingu-15”, ilungise ukubekezelelana kufikela ku-0.01mm Max.300T ingcindezi

ISIBONISI SESIKRINI SOKUTHINTA SE-LED ●Isikrini sokuthinta se-LED esinencazelo ephezulu esingu-15”, umqhubi angabuka zonke izilungiselelo endaweni ehlukile, anciphise isikhathi sokushintsha umsebenzi futhi athuthukise ukusebenza kahle.

UHLELO LOKUNXIBISA Uhlelo lokungcwalisa oluzenzakalelayo olulawulwa yikhompyutha Ukulungiswa okulula

ISIGABA ESISIKHIWA NGOKUFA Uhlelo lomugqa ophakathi Ukukhiya komoya kokujaha okungaphezulu nangaphansi Shintsha ukuze uthole ukuthi amapuleti akhiyiwe endaweni efanele

UKULETHWA Ukuphakama okuphezulu kwenqwaba 1350mm Ukulethwa okungenasiphelo

I-feeder yekhwalithi ephezulu enama-suckers angu-4 okuphakamisa iphepha kanye nama-suckers angu-4 okudlulisa iphepha iqinisekisa iphepha lokudla elizinzile nelisheshayo. Ukuphakama kanye ne-engeli yama-suckers kungalungiseka kalula ukuze kugcinwe amashidi eqondile ngokuphelele.

Isitholi seshidi eliphindwe kabili esisebenza ngomshini, idivayisi evimba amashidi, umshini womoya olungisekayo uqinisekisa ukuthi amashidi adluliselwa etafuleni lebhande kancane kancane nangokunembile.

Iphampu ye-vacuum ivela ku-German Becker.

Ukulungiswa kwenqwaba ohlangothini oluphambene kulawulwa yinjini ukuze kunikezwe ukudla okunembile kweshidi.

Uhlelo lokulayisha kusengaphambili, ukudla okungayeki, inqwaba ephezulu (Ukuphakama okuphezulu kwenqwaba kufinyelela ku-1600mm).

Izinqwaba eziphelele zingakhiwa kuma-pallet asebenza ezitimeleni zesistimu yokulayisha ngaphambi kokulayisha. Lokhu kwenza umnikelo omkhulu ekukhiqizeni okubushelelezi futhi kuvumela opharetha ukuthi ahambise inqwaba elungisiwe endaweni yokudla ngokunembile nangokulula.

I-clutch yomshini esebenza nge-pneumatic esebenza ngesikhundla esisodwa iqinisekisa ukuthi ishidi lokuqala ngemva kokuqala kabusha komshini lihlala linikezwa ama-lays angaphambili ukuze kube lula, konge isikhathi futhi konge izinto.

Ama-side lays angashintshwa ngqo phakathi kwemodi yokudonsa neyokucindezela ezinhlangothini zombili zomshini ngokumane uphendule ibhawodi ngaphandle kokufaka noma ukususa izingxenye. Lokhu kunikeza ukuguquguquka kokucubungula izinto eziningi ezahlukene: kungakhathaliseki ukuthi izimpawu zokubhalisa zingakwesobunxele noma kwesokudla seshidi.

Izitebhisi eziseceleni nangaphambili zinezinzwa zokukhanya ezinembile, ezingakwazi ukubona umbala omnyama kanye nephepha lepulasitiki. Ukuzwela kuyalungiseka.

Izinzwa ezibonakalayo ezinesistimu yokumisa ezenzakalelayo etafuleni lokuphakelayo zikuvumela ukuthi uthuthukise ukuqapha kwesistimu - ukuze uthole ukulawula okuphelele kwekhwalithi phezu kobubanzi beshidi lonke kanye nokugcwala kwephepha.

Iphaneli yokusebenza yengxenye yokondla kulula ukuyilawula inqubo yokondla ngesibonisi se-LED.

Izilawuli zokushayela ezihlukile zenqwaba eyinhloko kanye nenqwaba eyisizayo

I-PLC kanye nekhamera ye-elekthronikhi yokulawula isikhathi

Idivayisi elwa nezithiyo ingagwema umonakalo womshini.

Ibhande lokudlulisa le-Swiss Rapplon le-feeder futhi ijubane liyalungiseka

Uhlelo lokukhiya lwe-pneumatic lwenza kube lula ukukhiya nokukhulula ipuleti lokujaha nokusika.

Ipuleti lokusika eliphakamisa umoya ukuze kube lula ukushelela nokungena.

Uhlelo lwe-centerline olusebenzisa i-die-cutting chase olunokulungiswa okuncane okunqamulayo luqinisekisa ukubhaliswa okunembile okuholela ekushintsheni umsebenzi ngokushesha.

Ukubekwa okunembile kwe-Cutting chase okulawulwa yizinzwa zokukhanya ezinembile ngedivayisi yokuhlola ezenzakalelayo

Idivayisi yokushintshana yokujaha yokusika

Injini eyinhloko ye-Siemens elawulwa yi-inverter ye-Schneider.

Ukulungiswa okuncane kwamandla okusika (ukunemba kwengcindezi kungafika ku-0.01mm we-encoder, ukucindezela okuphezulu kokusika ngodayi kungafika ku-300 tons) ngegiya lezibungu eliqhutshwa yi-servo motor futhi lilawulwa kalula ngesikrini sokuthinta esingu-15 intshi.

I-crankshaft yenziwe ngensimbi engu-40Cr.

Insimbi ethambile ye-HT300 yamafreyimu omshini nama-platens

Amasethi ayi-7 ezinsimbi zokubopha ezinezinsimbi zokubopha ezenziwe nge-aluminium alloy elula futhi eqinile ene-ultra hard coat kanye ne-anodized finish aqinisekisa ukubhaliswa kwephepha okunembile nokungaguquguquki.

Ibha yegripper eklanywe ngendlela ehlukile ayidingi sikhala sokufaka isikhala sokuqinisekisa ukubhaliswa kwephepha okunembile

I-Renold chain esezingeni eliphezulu evela eNgilandi enokwelashwa okunwetshiwe kusengaphambili iqinisekisa ukuzinza nokunemba ngokuhamba kwesikhathi.

Uhlelo lokushayela olunenkomba yokucindezela okuphezulu lokulawula ukubeka indawo kwebha yegripper

Idivayisi yokuvikela ukulayisha ngokweqile ene-torque limiter idala izinga eliphezulu lokuphepha kumqhubi kanye nomshini.

Uhlelo lokuthambisa nokupholisa oluzenzakalelayo lwe-drive eyinhloko kanye nokuthambisa okuzenzakalelayo kweketanga eliyinhloko.

Cukwakhekas

—— ...–

IBHOKISI LESIKHOMBISO SASE-TAIWANIbhande Le-synchronical lase-USAI-SIEMENS MOTOR

I-UK Renold ChainI-GRIPPER YASEJAPANIphampu likaBecker

—— ...–

IBHODHODI LOKUKHUPHA NOKUQEDA IZINTO EZIJWAYELEKILE

UKUHLELWA KWESITESHI

UHLELO LWESITESHI

—— ...–

Iyunithi Yokulethwa

Ibhulashi lokubhuleka elilungisekayo elilawulwa yinjini ye-AC lisiza ekukhipheni iphepha kusuka kugripha bese liqoqa iphepha ngesivinini esiphezulu kanye nokulungiswa okuphelele.

Ukuphakama kwenqwaba yokulethwa kufinyelela ku-1050mm.

Amadivayisi e-photoelectric avimbela ukwenyuka ngokweqile kanye nokwehla ngokweqile kwenqwaba yephepha lokulethwa

Inqwaba ingabalwa ngenzwa yokukhanya (ejwayelekile).

Umshini wonke ungalungiswa ngesikrini sokuthinta esingu-10.4 intshi ohlangothini olungemuva

I-rack yokulethwa eyisizayo ilungiselelwe ukulethwa okungapheli.

Izingxenye Zikagesi

Ama-detector kagesi, amaseli e-micro switched kanye ne-photoelectric alawulwa yi-PLC kuwo wonke umshini

I-Omron Electronic cam switch kanye ne-encoder

Yonke imisebenzi emikhulu ingenziwa ngesikrini sokuthinta esingu-15 no-10.4 intshi.

Ukudluliselwa kokuphepha kwe-PILZ njengenjwayelo kuqinisekisa izinga eliphezulu lokuphepha.

Iswishi yangaphakathi yokukhiya ihlangabezana nemfuneko ye-CE.

Ifaka izingxenye zikagesi ezifaka phakathi iMoeller, i-Omron, iSchneider relay, i-AC contactor kanye ne-air breaker ukuqinisekisa ukuzinza ngokuhamba kwesikhathi.

Ukuboniswa kwamaphutha okuzenzakalelayo kanye nokuzihlola ngokwakho.

IIdatha yokufaka

—— ...–

Okuyinhlokoizinto

—— ...–

Ikhadibhodi Lephepha Ibhodi eliqinile eliqinile

Ipulasitiki eqinile kancane Ibhodi likathayela Ifayela lephepha

—— ...–

Amasampula Ohlelo Lokusebenza