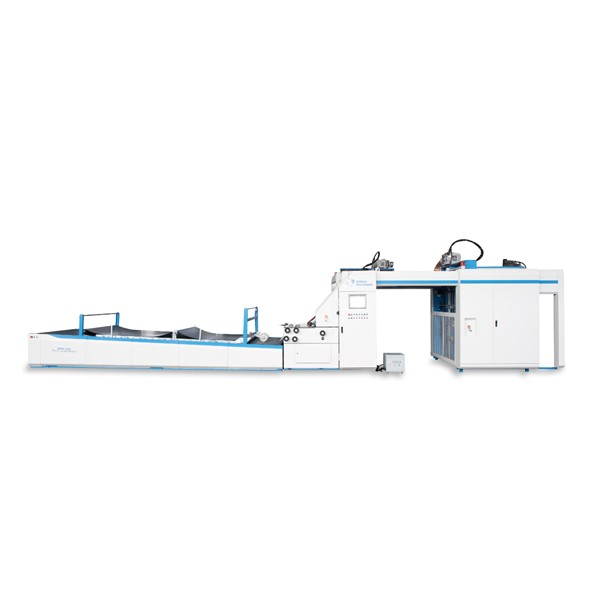

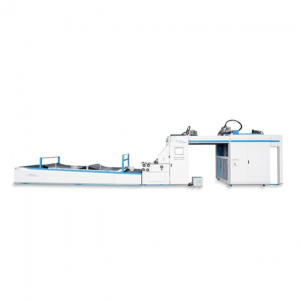

Umshini wokulaminetha we-flute we-EUFM ozenzakalelayo ozenzakalelayo

Iphepha lingafakwa i-laminate ngebhodi lephepha ukuze kwandiswe amandla nobukhulu bezinto noma imiphumela ekhethekile. Ngemva kokusikwa kwe-die, lingasetshenziswa emabhokisini okupakisha, amabhodi okukhangisa nezinye izinjongo.

| Imodeli | I-EUFM1450 | I-EUFM1650 | I-EUFM1900 |

| Usayizi omkhulu | 1450*1450mm | 1650*1650mm | 1900*1900mm |

| Usayizi omncane | 380*400mm | 400*450mm | 450*450mm |

| Iphepha | 120-800g | 120-800g | 120-800g |

| Iphepha elingezansi | Ibhodi elihlanganisiwe le-ABCDEF elingu-≤10mm ≥300gsm | Ibhodi elihlanganisiwe le-ABCDEF elingu-≤10mm ≥300gsm | ≤10mm ABCDEF ibhodi elihlanganisiwe ≥300gsm ikhadibhodi |

| Isivinini esikhulu sokubopha | 150m/min | 150m/min | 150m/min |

| Amandla | 25kw | 27kw | 30KW |

| Ukunemba kwenduku | ±1.5mm | ±1.5mm | ±1.5mm |

1. UKUDLA OKUNGEZANSI KWESHIDI

Sebenzisa uhlelo lokulawula ugesi lwe-Servo motor olungenisiwe, olunebhande lokumunca laseJapan NITTA ukwenza i-inverter yamandla okumunca, kanye nebhande elihlanzwa nge-water roller; Ubuchwepheshe obunelungelo lobunikazi bokuqinisekisa ukuthi i-corrugate kanye nekhadibhodi zisebenza kahle futhi kulula.

2. Indlela Yokuphakela Ishidi Eliphezulu

Kokubili umlomo wokuphakamisa iphepha kanye nowokuphakela we-feeder ezinikele ngokuzenzakalela esheshayo ungalungiswa ngokukhululekile ukuze uvumelane nephepha elincane nelijiyile. Kanye nephampu ye-Becker, qinisekisa ukuthi iphepha lokuphakelayo eliphezulu lisebenza ngokushesha nangokushelela.

3. UHLELO LIKAGESI

Yaklama futhi yamukela isilawuli sokunyakaza sase-USA Parker kanye nohlelo lwe-Yaskawa Servo kanye ne-inverter, i-Siemens PLC ukuqinisekisa ukuthi umshini usebenza ngesivinini esiphezulu kanye nokunemba njengokusebenza okuphezulu kanye nokuqina kokusebenza.

4. INGXENYE YOKUQALA OKUSETSHENZISWAYO

Uhlelo olusethwe kusengaphambili olunomsebenzi osethwe kusengaphambili lungasethwa njengosayizi wephepha ngesikrini sokuthinta futhi luqondiswe ngokuzenzakalelayo ukuze kuncishiswe isikhathi sokusetha ngempumelelo.

5. Uhlelo Lokudlulisa

Ibhande le-synchronical lamasango kanye ne-SKF bearing njenge-main transmission liyasetshenziswa ukuqinisekisa ukuzinza. Zombili ama-pressure rollers, i-dampening roller kanye ne-glue value zingalungiswa kalula ngesibambo nge-mechanical encoder.

6. UHLELO LOKUBEKA IZIMO

I-Photocell kanye ne-Parker Dynamic module kanye nohlelo lwe-Yaskawa Servo kuqinisekisa ukunemba kokuqondiswa kwephepha eliphezulu nelingezansi. I-roller ye-glue yensimbi engagqwali enokugaya okuhle kwe-anilox ukuqinisekisa ukumbozwa kwe-glue ngokulinganayo ngisho noma kuncane kakhulu.

7. Isikrini Sokuthinta kanye Nokuqondiswa Okuzenzakalelayo

Ifomethi yephepha ingasethwa nge-Touch Monitor engu-15 intshi futhi iqondiswe nge-inverter motor ngokuzenzakalelayo ukuze kuncishiswe isikhathi sokusetha. Ukuqondiswa okuzenzakalelayo kusetshenziswa kuyunithi yangaphambi kwenqwaba, iyunithi yokudla ephezulu, iyunithi yokudla engezansi kanye neyunithi yokubeka. Inkinobho yochungechunge lwe-Eaton M22 iqinisekisa isikhathi eside somsebenzi kanye nobuhle bomshini.

8. UMTHUTHI

Iyunithi yokuhambisa ephakanyisiwe yenza kube lula kumqhubi ukukhulula iphepha. Iyunithi yokuhambisa ende kanye nebhande lokucindezela ukwenza umsebenzi onamathelisiwe wome ngokushesha.

9. UHLELO LOKUNXIBISA NGOKWENZAKALELAYO

Iphampu yokugcoba ezenzakalelayo yazo zonke izinhlobo zebhere eliyinhloko iqinisekisa ukukhuthazela okuqinile komshini ngisho nangaphansi kwesimo sokusebenza esinzima.

IZINKETHO:

1. UHLELO LOKUDLA LOKUPHEPHA OLWENZA UMPHETHO OPHEZULU

Unqenqema lomthofu luqinisekisa ukuthi ibhodi elijiyile eligoqekile elinjengezendlalelo ezi-5 noma ezi-7 lihamba kahle ngisho noma lisesimweni sokuphola kakhulu.

2. ISIPHO SE-SERVO ESINGENAMSHAFTI

I-servo feeder engenashaft isetshenziselwa ishidi elide kakhulu ngokunyakaza okuguquguqukayo.

3. UMqaphi Wokuphepha Owengeziwe kanye Nokudluliselwa Kokuphepha

Isembozo esivaliwe kakhulu esizungeze umshini ukuze uthole usizo olwengeziwe lokuphepha. Ukudluliselwa kokuphepha ukuqinisekisa ukuthi iswishi yomnyango kanye ne-E-stop kusebenza njalo.