I-GUOWANG C106 IZENZAKALO EZIZENZEKELAYO ZOKUDAYISA NGOKUNGENAKHI

Intloko yesondlo esemgangathweni ophezulu

Inkqubo yomgca osembindini

Ukuleqa i-wheat lock ye-pneumatic

Ukondla nokuhambisa ukutya rhoqo

IiSheets ezingama-7500/H

Uxinzelelo lwe-Max.300T

Isikrini sokuchukumisa kabini ukuze kube lula ukusebenza

Isinyithi esityhidiweyo se-HT500-7

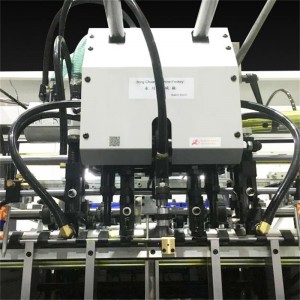

INTLOKO YOKUTYA I-feeder esemgangathweni ophezulu, ii-sucker ezi-4 kunye nee-forwarder ezi-4

I-FEEDER Isixhobo esifakwe iinqwaba kwangaphambili, Ukutyisa okungayekiyo Ukuphakama kweenqwaba yi-1600mm

IPOMPU YOMOYA YASEJAMANI UBECKER

ITHEYIBHILE YOKUTYA Ibhanti yokuhambisa iNitta Itheyibhile yokuhambisa yentsimbi engatyiwayo

ICANDELO LOKUKHUPHA Inkqubo yomgca osembindini Ukuphakamisa umdyarho ophezulu we-pneumatic Ukwahlula ikhamera ukuya kwindawo yokulawula yomdyarho ophezulu, ophakathi, nophantsi Umgangatho ophezulu wemveliso ngokukhupha ngokuzenzekelayo

ICANDELO ELIQAQAYO I-Servo motor evela eJapan FUJI Uxinzelelo lunokulungiswa kwiscreen sokuchukumisa se-15”, lulungelelanisa ukunyamezela ukuya kuthi ga kuxinzelelo lwe-0.01mm Max.300T

I-LED TICK SCREN MONITOR ●Isikrini sokuchukumisa se-LED esine-15” ephezulu, umqhubi unokujonga zonke izicwangciso kwindawo eyahlukileyo, anciphise ixesha lokutshintsha umsebenzi kwaye aphucule ukusebenza kakuhle.

INKQUBO YOKUTYA Inkqubo yokuthambisa ezenzekelayo elawulwa yikhompyutha Ukulungiswa okulula

ICANDELO ELISIKA UKUFA Inkqubo yomgca osembindini Isitshixo se-pneumatic sokugxotha i-die ephezulu nesezantsi Tshintshela ukuze ubone ukuba iipleyiti zitshixiwe kwindawo echanekileyo

UKUHANJISWA Ukuphakama okuphezulu kwenqwaba 1350mm Ukuhanjiswa okungayekiyo

I-feeder esemgangathweni ophezulu enezikhongozeli ezi-4 zokuphakamisa iphepha kunye nezikhongozeli ezi-4 zokuhambisa iphepha ziqinisekisa ukuba iphepha lokutyisa lizinzile kwaye likhawuleza. Ukuphakama kunye ne-engile yezikhongozeli kulula ukuzilungisa ukuze zigcine amaphepha ethe tye ngokupheleleyo.

Isixhobo sokubona amaphepha amabini esisebenza ngoomatshini, isixhobo esithintela amaphepha, isixhobo sokufutha umoya esihlengahlengiswayo siqinisekisa ukuba amaphepha adluliselwa kwitafile yebhanti ngokuthe chu nangokuchanekileyo.

Impompo ye-vacuum ivela kwiGerman Becker.

Ukulungiswa kweenqwaba kwicala elinqamlezileyo kulawulwa yimoto ukuze kufakwe ishiti ngokuchanekileyo.

Inkqubo yokulayisha ngaphambi kwexesha, ukondla rhoqo, inqwaba ephezulu (Ukuphakama okuphezulu kwenqwaba kufikelela kwi-1600mm).

Iinqwaba ezigqibeleleyo zinokwenziwa kwiipalethi ezisebenza kwiireyili zenkqubo yokulayisha kwangaphambili. Oku kwenza igalelo elikhulu kwimveliso egudileyo kwaye kuvumela umsebenzisi ukuba ahambise inqwaba elungisiweyo kwindawo yokutya ngokuchanekileyo nangokulula.

I-clutch yoomatshini esebenza nge-pneumatic esebenza kwindawo enye iqinisekisa ukuba iphepha lokuqala emva kokuqalisa kwakhona komatshini lihlala linikwa ii-lays zangaphambili ukuze kube lula, konge ixesha kwaye konge izinto.

Ii-side lays zingatshintshwa ngqo phakathi kwe-draw kunye ne-push mode kumacala omabini omatshini ngokujika nje i-bolt ngaphandle kokongeza okanye ukususa iindawo. Oku kubonelela ngokuguquguquka kokucubungula uluhlu olubanzi lwezinto: nokuba iimpawu zokubhalisa zingasekhohlo okanye ngasekunene kwephepha.

Iilayini ezisecaleni nangaphambili zinezixhobo zokubona ezichanekileyo, ezinokubona umbala omnyama kunye neplastiki. Uvakalelo luyakwazi ukuhlengahlengiswa.

Izinzwa ze-Optical ezinenkqubo yokumisa ngokuzenzekelayo etafileni yokutya zikuvumela ukuba ulungiselele ukujonga inkqubo- ukuze ufumane ulawulo olupheleleyo lomgangatho kulo lonke ububanzi bephepha kunye nokuxinana kwephepha.

Iphaneli yokusebenza yenxalenye yokondla kulula ukuyilawula inkqubo yokondla nge-LED displayer.

Ulawulo olwahlukileyo lokuqhuba lwenqwaba ephambili kunye nenqwaba encedisayo

I-PLC kunye nekhamera ye-elektroniki yokulawula ixesha

Isixhobo esichasene nemiqobo singayiphepha ingozi yomatshini.

Ibhanti yokuhambisa yeSwiss Rapplon ye-feeder kwaye isantya siyalungiseka

Inkqubo yokutshixa yomoya yenza kube lula ukutshixa nokukhulula ipleyiti yokutshixa nokusika.

Ipleyiti yokusika ephakamisa umoya ukuze kube lula ukungena nokuphuma.

Inkqubo ye-centerline ekulandeleni i-die-cutting kunye nokulungiswa kwe-transversal micro iqinisekisa ubhaliso oluchanekileyo olukhokelela ekutshintsheni umsebenzi ngokukhawuleza.

Indawo echanekileyo yokuQokelela iCutting elawulwa zii-precision optical sensors ezinesixhobo sokutshixa esizenzekelayo

Isixhobo sokujika esinqumlezayo

Injini ephambili yeSiemens elawulwa yi-inverter yeSchneider.

Ukulungiswa okuncinci kwamandla okusika (ukuchaneka koxinzelelo kungafikelela kwi-0.01mm ye-encoder, uxinzelelo oluphezulu lokusika idayi lufikelela kwiitoni ezingama-300) ngegiya ye-worm eqhutywa yi-servo motor kwaye ilawulwa lula ngesikrini sokuchukumisa se-intshi ezili-15.

I-crankshaft yenziwe ngentsimbi ye-40Cr.

Isinyithi esithambileyo se-HT300 seefreyimu zoomatshini kunye neeplatens

Iiseti ezisi-7 zeebha zegripper ezineegripper ezenziwe nge-alloy ye-aluminium elula nehlala ixesha elide ene-ultra hard coat kunye ne-anodized finish ziqinisekisa ukubhaliswa kwephepha ngokuchanekileyo nangokuhambelanayo.

Ibha yegripper eyilwe ngendlela eyahlukileyo ayifuni sithuba semali ukuze ihlawulwe ukuqinisekisa ukubhaliswa kwephepha ngokuchanekileyo

I-Renold chain esemgangathweni ophezulu evela eNgilane enonyango olusele lulungisiwe iqinisekisa uzinzo kunye nokuchaneka ekuhambeni kwexesha.

Inkqubo yokuqhuba i-index yoxinzelelo oluphezulu yolawulo lokubeka indawo kwi-gripper bar

Isixhobo sokukhusela umthwalo omninzi esinomda we-torque senza ukhuseleko oluphezulu kumqhubi nakumatshini.

Inkqubo yokuthambisa nokupholisa ngokuzenzekelayo kwi-main drive kunye nokuthambisa ngokuzenzekelayo kwi-main chain.

Cumfanekisos

—— ...–

IBHOKISI YESALATHISO SASE-TAIWANIbhanti ye-US SynchronicalImoto ye-SIEMENS

I-UK Renold ChainI-GRIPPER YASEJAPANImpompo kaBecker

—— ...–

UMGANGATHO WEBHODHODI YOKUKHUPHA NOKUKHULULA

UYILO LOMGANGATHO

ICEBO LAPHANTSI

—— ...–

Iyunithi yokuhanjiswa

Ibhrashi yokuqhobosha ehlengahlengiswayo elawulwa yi-AC motor inceda ekukhupheni iphepha kwigripper kunye nokuqokelela iphepha ngesantya esiphezulu kunye nokulungelelaniswa okugqibeleleyo.

Ukuphakama kwenqwaba yokuhambisa kufikelela kwi-1050mm.

Izixhobo zombane ezithintela ukunyuka nokuhla kakhulu kwenqwaba yephepha lokuhambisa

Inqwaba ingabalwa nge-optical sensor (esemgangathweni).

Lonke umatshini ungalungiswa ngesikrini sokuchukumisa se-intshi ezili-10.4 kwicala elingasemva

Irakhi yokuhambisa encedisayo yenzelwe ukuhanjiswa okungapheliyo.

Izixhobo zombane

Izixhobo zokubona izinto ze-elektroniki, ii-micro switched kunye nee-photoelectric cells ezilawulwa yi-PLC kumatshini wonke

Iswitshi yekhamera ye-elektroniki ye-Omron kunye ne-encoder

Lonke usebenzo olukhulu lungenziwa nge-touch monitor ye-intshi ezili-15 kunye ne-10.4.

I-PILZ safety relay njengomgangatho iqinisekisa umgangatho wokhuseleko ophezulu.

Iswitshi yangaphakathi yokutshixa iyahlangabezana neemfuno ze-CE.

Isebenzisa izixhobo zombane eziquka iMoeller, iOmron, iSchneider relay, iAC contactor kunye neair breaker ukuqinisekisa uzinzo kwixesha elide.

Ukubonisa iimpazamo ngokuzenzekelayo kunye nokuzixilonga ngokwakho.

IIdatha yokufakela

—— ...–

Eyona iphambiliizinto

—— ...–

Ikhadibhodi yephepha Ibhodi eqinileyo

Iiplastiki eziqinileyo kancinci Ibhodi yekhonkrithi Ifayile yephepha

—— ...–

Iisampulu zesicelo