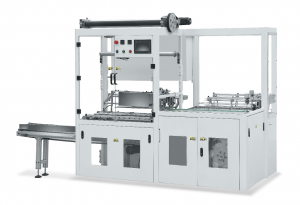

Mochini oa ho itšeha le ho cheka oa Roll Feeder

| Mohlala | FD970x550 |

| Sebaka se Seholo sa ho Seha | 1050mmx610mm |

| Ho seha ka nepo | 0.20mm |

| Boima ba Pampiri ea Gram | 135-400g/㎡ |

| Bokgoni ba Tlhahiso | Makgetlo a 100-180/motsotso |

| Tlhokahalo ea Khatello ea Moea | 0.5Mpa |

| Tšebeliso ea Khatello ea Moea | 0.25m³/motsotso |

| Khatello e Kholo ea ho Seha | 280T |

| Bophara ba Max Roller | 1600 |

| Matla a Feletseng | 12KW |

| Tekanyo | 5500x2000x1800mm |

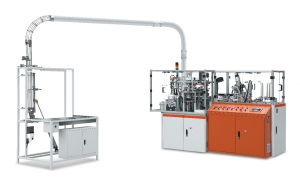

Mochini oa FDZ oa ho seha webo o iketsang o thehiloeng theknolojing e tsoetseng pele ea machaba, o na le botsitso bo phahameng, ts'ebetso e phahameng ea polokeho, ho nepahala ho phahameng ha sehlahisoa se felileng, o sebelisoa haholo indastering ea khatiso, ea ho paka le ea lihlahisoa tsa pampiri. O sebelisa micro-computer, sebopeho sa taolo ea motho le khomphutha, servo positioning, alternating current frequency converter, ho bala ka boiketsetso, poleiti ea ho notlela ea pneumatic ka letsoho, sistimi ea ho kheloha ha photoelectric correcting, clutch ea electromagnetic, centralized oil lubrication, tšireletso ea overload le gearing e ikhethang. Kahoo o tiisa ts'ebetso e boreleli ea pampiri e khutlang le pampiri ea ho fepa, ho beha hantle le ho hula ka mokhoa o hlophisehileng. Likarolo tsohle tsa bohlokoa le taolo ea mochini lia kenngoa. Ho kenya ho joalo ho ka etsa hore mochini o be le khatello e tsitsitseng, ho beha hantle, ho tsamaea hantle, polokeho le ts'epo.

1. Sebopeho sa Lisebelisoa tsa Liboko: Sistimi e phethahetseng ea phetisetso ea lebili la liboko le liboko e netefatsa khatello e matla le e tsitsitseng 'me e etsa hore ho sehoe ka nepo ha mochini o ntse o sebetsa ka lebelo le phahameng, o na le likarolo tsa lerata le tlase, ho sebetsa hantle le khatello e phahameng ea ho seha.

Foreimi e ka sehloohong ea motheo, foreimi e tsamaeang le foreimi e ka holimo kaofela li sebelisa Ductile Cast Iron QT500-7 e matla haholo, e nang le litšobotsi tsa matla a ho tensile a phahameng, e thibelang ho fetoha ha sebopeho le e thibelang ho khathala.

2. Sistimi ea ho tlotsa: E amohela sistimi ea ho tlotsa e qobelloang ho netefatsa hore oli e tsamaisoang ka sehloohong e fumaneha khafetsa le ho fokotsa khohlano le ho lelefatsa bophelo ba mochini, mochini o tla tima bakeng sa tšireletso haeba khatello ea oli e le tlase. Potoloho ea oli e eketsa sefe ho hloekisa oli le switch ea phallo ho lekola oli e haellang.

3. Matla a ho seha die a fanoa ke mokhanni oa enjene ea inverter ea 7.5KW. Hase feela ho boloka matla, empa hape ho ka etsa hore lebelo la li-steeples le fetohe, haholo-holo ha le hokahanngoa le lebili le leholo haholo, le etsang hore matla a ho seha die a be matla le a tsitsitseng, 'me motlakase o ka fokotsoa haholoanyane.

Brake ea clutch ea pneumatic: fetola khatello ea moea ho laola torque ea ho khanna, lerata le tlase le ts'ebetso e phahameng ea brake. Mochini o tla tima ka bohona haeba ho ka etsahala hore ho be le ho feta tekano, ho arabela ka potlako le ka potlako.

4. Khatello ea taolo ea motlakase: e nepahetse ebile e potlakile ho fihlela phetoho ea khatello ea ho seha ka ho cheka, Khatello e fetoloa ka bo eona ka enjene ho laola maoto a mane ka HMI. E bonolo haholo ebile e nepahetse.

5. E ka seha ka die-cut ho latela mantsoe le dipalo tse hatisitsoeng kapa ea seha ka die-cut ntle le tsona. Khokahano pakeng tsa stepping motor le photoelectric eye tse ka khethollang mebala li netefatsa ho lekana hantle ha boemo ba die-cut le dipalo. Beha bolelele ba phepelo ka har'a molaoli oa micro-computer ho seha lihlahisoa ntle le mantsoe le dipalo.

6. Khabinete ea motlakase

Motlakase:

Sesebelisoa sa ho fetolela maqhubu se laola enjene e kholo, ka likarolo tsa matla a tlase le bokhoni bo phahameng.

PLC le HMI:

skrineng ho bonts'a data le boemo bo sebetsang, liparamente tsohle li ka beoa skrineng.

Sistimi ea taolo ea motlakase:

E amohela taolo ea likhomphutha tse nyane, ho lemoha le ho laola sekhutlo sa encoder, ho lelekisa le ho lemoha ka photoelectric, ho fihlela ka ho fepa pampiri, ho fetisa, ho seha le ho fana ka ts'ebetso ea taolo le ho lemoha ka boiketsetso.

Lisebelisoa tsa ts'ireletso:

Mochini o tšosa ha ho etsahala phoso, 'me o tima ka bohona bakeng sa tšireletso.

7. Yuniti ea Tokiso: Sesebelisoa sena se laoloa ke Motlakase, o ka lokisang le ho lokisa pampiri boemong bo nepahetseng. (ka letsohong le letšehali kapa ka ho le letona)

8. Lefapha la ho seha die le amohela mofuta wa sesebediswa sa ho notlela ka moya ho qoba ho tswa mochining.

Poleiti ea ho itšeha ka ho tjhesa: Phekolo ea ho futhumatsa poleiti ea tšepe ea 65Mn, ho ba thata haholo le ho ba bataletse.

Poleiti ea thipa e sehang ka ho tjhesa le foreimi ea poleiti li ka ntšoa e le hore li ka boloka nako ea ho fetola poleiti.

9. Alamo e thibiloeng ka pampiri: sistimi ea alamo e etsa hore mochini o eme ha ho fepeloa pampiri ho thibiloeng.

10. Yuniti ea ho Fepa: E amohela rolara ea pneumatic ea mofuta oa ketane e phutholohileng, khatello ea maikutlo e laola lebelo la ho phutholoha, 'me seo ke hydraumatic, e ka tšehetsa bonyane 1.5T. Bophara bo boholo ba pampiri ea roll ke 1.6m.

11. Thepa ea ho kenya: Ho kenya thepa ea motlakase ka har'a roll, e leng ntho e bonolo le e potlakileng. Lirolara tse peli tse koahetsoeng ka rabara li laoloa ke Traction Motor, kahoo ho bonolo haholo ho etsa hore pampiri e tsamaee ka bo eona.

12. Mena le ho batalatsa thepa e kobehileng ka bohona karolong e ka hare ea pampiri. E entse phetoho ea mekhahlelo e mengata ea tekanyo ea ho mena. Ho sa tsotelehe hore na sehlahisoa se kobehile hakae, se ka batalatsoa kapa sa menahanngoa hape ho ea mahlakoreng a mang.

13. Thepa ea ho fepa: sistimi ea ho latela mahlo ea photoelectric e netefatsa ho hokahanya ha ho fepa thepa le lebelo la ho seha ka dies.

14. Ka ketso ea switch ea induction ea mokhatlo, sehlahisoa se felileng se tla theoleloa ka bohona ho lula bophahamo ba pampiri ea ho tlatsa bo sa fetoha, nakong ea ts'ebetso eohle ea ho seha ka dae, ho nka pampiri ka letsoho ha ho hlokahale.

Khetho. Yuniti ea ho Fepa: E adoptha ebile ha e na shaft ea hydraulic, e ka tšehetsa 3'', 6'', 8'', 12''. Bophara bo boholo ba pampiri ea moqolo ke 1.6m.

| Enjene ea Litepisi | Chaena |

| Enjene ea ho lokisa khatello | Chaena |

| Mokhanni oa Servo | Schneider (Fora) |

| Sensor ea 'Mala | Ho kula (Jeremane) |

| PLC | Schneider (Fora) |

| Phetoho ea maqhubu | Schneider (Fora) |

| Likarolo tse ling tsohle tsa motlakase | Jeremane |

| Switch ea motlakase oa letsatsi | Ho kula, Jeremane |

| Silindara e kholo ea moea | Chaena |

| Valve e kholo ea Solenoid | AirTAC (Taiwan) |

| Clutch ea pneumatic | Chaena |

| Li-bering tse kholo | Japane |