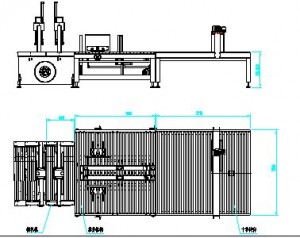

SAIOB-Vucuum nuugid Flexo Daabacaadda & Goynta & Jaritaanka iyo Koolada ee Khadka

| Magaca | Tirada |

| Qaybta quudinta (Quudiyaha Cidhifka Lead) | 1 |

| Qaybta daabacaadda (Roogga anilox ee dhoobada ah + Daab) | 4 |

| Cutubka Slotting (Usha laba-geesoodka ah) | 1 |

| Cutubka jarista Die | 1 |

| Qalabka dhejiska otomaatiga ah | 1 |

SAIOB-Vacuum nuugista Flexo Daabacaadda & Goynta & jarista iyo xabagta ee safka ku jira

(Qaab-dhismeedka shaqada iyo xuduudaha farsamada)

Cutubka hawlgalka ee kombiyuutarku xakameeyo

1. Mashiinku wuxuu qaataa xakamaynta kumbuyuutarka, iyadoo darawalka servo-ga Japan uu shaqeynayo.

2. Qalab kastaa wuxuu ku qalabaysan yahay shaashad taabasho oo HMI ah oo leh hawlgal fudud, hagaajin sax ah iyo eber otomaatig ah.

3. Shaqada xusuusta: marka xogta saxda ah la geliyo si toos ah ayaa loo keydiyaa isticmaalka xiga. Shaqada xusuusta 9999.

4. Xogta si gaar ah ayaa loo hagaajin karaa, iyada oo aan la isticmaalin shaqada dalabka. Hawl-wadeenku si toos ah ayuu u socodsiin karaa xogta gelinta madaxbannaan isagoo adeegsanaya nidaamka dejinta sanduuq keliya. Dhererka, ballaca iyo dhererka sanduuqa waa la gelin karaa cutubka booskana si toos ah ayuu u dejin doonaa.

5. Mashiinka si madax-bannaan ayaa loo hagaajin karaa ka dibna xogta cusub ayaa la cusbooneysiiyaa marka ay soo muuqato waxay u oggolaanaysaa hawlwadeenka inuu arko cilladda ku jirta mashiinka oo shaqeynaya.

6. Nidaamka kaydinta xogta haddii ay dhacdo luminta xusuusta. Xogta si fudud ayaa loo soo celin karaa.

7. Haddii mashiinka loo baahdo in la furo inta uu shaqeynayo, marka la xiro mashiinku si toos ah ayuu ugu soo laaban doonaa booskiisii asalka ahaa.

8. Qaadista anilox si otomaatig ah si loo badbaadiyo dhaqidda aan loo baahnayn.

9. Shaashadda ugu weyn ee mootada ayaa soo bandhigaysa xawaaraha, quudinta, iyo orodka

10. Shaashadda ugu weyn waxay soo bandhigaysaa nidaamka loo dejiyay, marka tirada dhabta ahna la soo saaro quudintu si toos ah ayay u joogsataa oo anilox-na si toos ah ayuu uga soo qaadaa saxanka.

11. Qaababka kartoonka ee hore loo sii diyaariyey ayaa diyaar ah.

12. Dhammaan cabbirrada si muuqata ayaa loo soo bandhigayaa.

13. Saddex sano oo casriyeyn software bilaash ah.

Cutubka quudinta wuxuu adeegsadaa tignoolajiyada quudinta geeska hogaanka JC, oo ku habboon dhammaan noocyada jiingadaha.

Roolaha quudinta oo ay wadaan 4 matoor oo servo ah, iyada oo aan lahayn qalad gudbin farsamo.

Cadaadiska hawada ee faakuumka waxaa lagu hagaajin karaa iyadoo loo eegayo cabbirka warqadda.

Duubista quudinta caagga sare ee laba-jibbaaran oo leh dhexroor 147.6mm ah

Bir laba-jibbaaran oo adag oo bir ah oo hoose oo leh dhexroor 157.45mm ah

Hagaajinta mootada oo leh bandhig dijitaal ah (0-12mm)

Waxaa ku qalabaysan qashinka nuugista iyo ka saarista boodhka. Tani waxay ka saartaa inta badan boodhka dusha sare ee daabacaadda, taasoo hagaajinaysa tayada daabacaadda.

Nidaamkan nuugista, dhaawaca ku yimaada xaashida jiingadda ayaa la yareeyaa, inkastoo ay jiraan isbeddello yar yar oo ku yimid dhumucda looxa, haddana tayada daabacadu ma saameynayso.

Qaybta quudinta si buuxda ayaa loo hagaajin karaa labadaba gacanta, iyada oo loo marayo matoorka iyo sidoo kale xakamaynta kumbuyuutarka CNC.

Auto Zero waxay u oggolaanaysaa mashiinka inuu furnaado, la hagaajiyo, la xidho oo dib loogu celiyo booska eber, taasoo badbaadinaysa waqtiga hawlwadeenka.

Dhexroorka dibadda 393.97 (oo ka kooban dhexroorka saxanka daabacaadda waa 408.37mm)

Sixitaanka dheelitirka joogtada ah iyo kan firfircoon, hawlgal siman.

Dhulka dusha sare leh oo leh dahaadh adag oo chrome ah.

Ku lifaaqida stereo-ga oo ay samaysay nidaamka ratchet qufulka degdega ah.

Dhululubada stereo-ga waxaa lagu kaxayn karaa baalka cagta ee hawlwadeenka si loo dejiyo.

1. Dhexroorka dibadda waa 172.2mm

2. Shiidi dusha sare ee birta ah, dahaadhka chrome-ka adag.

3. Sixitaanka dheelitirka iyo hawlgalka siman.

4. Hagaajinta nip-ka daabacaadda waxaa lagu dejiyaa kombiyuutar iyo kontorool dijital ah oo elektaroonik ah.

1. Dhexroorka dibadda waa 236.18mm.

2. Saldhigga birta ah oo leh dahaarka dhoobada.

3. Laysar lagu xardhay tilmaamaha macaamiisha.

4. Naqshad isbeddel degdeg ah si loo helo dayactir ku habboon

1. Dhexroorka dibadda waa 211mm

2.Steel dahaarka leh caag u adkaysta daxalka

3. Dhul leh taaj

5. Qol si gaar ah loogu talagalay oo shaabadaysan oo aluminium ah, kaas oo badbaadin kara ilaa 20% qashinka khad.

6. Waxaa lagu dahaadhay lakab cagaaran oo PTFE ah, kaas oo si fudud loo nadiifin karo oo aan dhegdheg lahayn.

7. Isticmaalka habka anilox-ka ee isbeddelka degdega ah ayaa la heli karaa ikhtiyaar ahaan.

1. Qalabka meeraha oo leh hagaajin 360 digrii ah

2. Booska dhinaca waxaa lagu hagaajin karaa koronto ahaan iyada oo loo marayo xakamaynta shaashadda taabashada ee PLC, ilaa masaafada 20mm, iyadoo la hagaajinayo micro ilaa 0.10mm.

3. Hagaajinta wareegga waxaa sameeya shaashadda taabashada PLC oo leh dhaqdhaqaaqa 360

4. Hagaajinta yar ee loo marayo inverter-ka si loo hagaajiyo ilaa 0.10mm

1. Bamka diaphragm-ka ee pneumatic wuxuu bixiyaa xasillooni khad ah, hawlgal fudud iyo dayactir.

2. Digniin khad hoose.

3. Shaandhada khad si looga takhaluso wasakhda.

1. Dhexroorka usha 154mm, oo chrome adag lagu dahaadhay.

2. Cadaadiska waxaa si koronto ah loogu hagaajiyaa 0-12mm waxaana lagu muujiyaa bandhig dijitaal ah.

1. Dhexroorka usha oo ah 174mm oo chrome adag lagu dahaadhay.

2. Ballaca mindiyaha daloolsan waa 7mm.

3. Mindiyaha waa bir adag, dhul godan oo simbiriirixan leh.

4. Mindi laba-qaybood ah oo sax ah oo goyn ah.

5. Saldhigga booska waxaa lagu dejiyaa shaashadda taabashada PLC oo leh xusuusta dalabka 1000.

Magdhawga

1. Magdhawga qalabka meeraha, hagaajinta dib u rogidda 360 digrii.

2. Wajiga daloolinta, mindi hore iyo gadaal loo isticmaalo PLC, xakamaynta shaashadda taabashada iyo hagaajinta 360 ee dijitaalka ah ee korontada ku shaqeeya.

Ikhtiyaarka qalabka godka gacanta

1. Iyada oo leh madaxyo aluminium ah iyo laba qalab oo la jarjaray (ballac 110).

Qaybta qalajiyaha infrared-ka (ikhtiyaar)

1. Qalabka qalajinta ee faakuumka caawiya; darawalka servo ee madaxa-bannaan.

2. Gudbinta faakuumka ee giraangiraha oo buuxa.

3. Kulayl la hagaajin karo iyadoo loo eegayo cabbirka warqadda.

4. Miiska wareejinta ee la qaadi karo.

Cutubka Jarida Die-Jarida (hal set)

Dhululubada dhimaha iyo farqiga anvil-ka ayaa si koronto ah loogu hagaajin karaa iyadoo la adeegsanayo bandhig dijitaal ah.

Hawlaha Hawlgalka

1. Silinda iyo anvil-ka, marka aan la shaqeyn, si toos ah ayaa loo furaa si loo yareeyo saameynta mashiinka loona kordhiyo cimriga urethane-ka.

2. Dhululubada dhimaha waxay leedahay hagaajin toosan oo ah 10mm.

3. Dhululubada Anvil waxaa lagu rakibay ficil ugaarsi oo otomaatig ah ilaa 30mm, kaas oo si siman u qaybiya meesha oo cimri dheereeya.

4. Mashiinku wuxuu ku qalabaysan yahay isku-dubarid anvil ah oo servo ah si uu gacan uga geysto hagaajinta saxnaanta anvils-ka duugoobay.

Silsiladda Die

1. Silinda dhimaha waa in lagula taliyaa iyadoo ku xiran qaabka

2. Bir qaab-dhismeed oo daawaha leh oo leh saxan chrome adag.

3. Godadka boolal ee hagaajinta birta ah waxaa loo kala qaybiyaa sida soo socota dhidibka 100mm, radial 18mm.

4. Dhererka gooyaha ee birta ah 23.8mm.

5. Dhumucda alwaaxda la jarjaray ee birta ah: 16mm (saddex lakab oo warqad ah)

13mm (shan warqad oo lakab leh)

Silsiladda Anvil

1. Dhululubo Urethane ah

2. Bir qaab-dhismeed oo daawaha leh oo leh saxan chrome adag.

3. Dhumucda urethane oo ah 10mm (dhexroorka 457.6mm) Ballaca 250mm (8 milyan oo cimri goyn ah)

Faylka Gluer

1. Suunka nuugista

2. Inverter-ka oo loo wado inuu xakameeyo saxnaanta farqiga

3. Xawaaraha isbedbeddela ee suunka bidix iyo midig si saxnaanta laabashada loo kordhiyo.

4. Gacmeedyada oo matoor leh

Jebinta Ka-saarista

1. Naqshadeynta rarista ugu sareysa ee loogu talagalay hawlgalka xawaaraha sare ee siman iyo eber shil marka la shaqeynayo wareegga xabagta ama shaqada SRP ee dibadda

2. Wareegga Servo-ka ku shaqeeya

3. Tirada saxda ah ee dufcadda

Tareenka ugu weyn ee qalabka gudbinta

1. Isticmaal bir bir ah oo kaarboor ah oo 20CrMnTi ah oo dhulka lagu shiiday

2. HRC 58-62 Adkaantu waxay bixisaa cimri dheer (ilaa 10 sano iyadoo aan lahayn xirasho yar)

3. Xidhiidh bilaash ah oo furaha ah si sax ahaanshaha muddada dheer

4. bamka saliidda ee laba-geesoodka ah oo leh buufin badan

| Faahfaahinta | 2500 x 1200 |

| Xawaaraha ugu badan (ugu yaraan) | 280 xaashi20 Xidhmo |

| Cabbirka Quudinta ugu badan (mm) | 2500 x 1170 |

| Cabbirka Quudiyaha Ka bood (mm) | 2500 x1400 |

| Cabbirka Quudinta ugu Yar (mm) | 650 x 450 |

| Baaxadda daabacaadda ugu badan (mm) | 2450 x1120 |

| Dhumucda Stereo-ga (mm) | 7.2mm |

| Guddiyada (mm) | 140x140x140x140240x80x240x80 |

| Cabbirka ugu badan ee la jarayo (mm) | 2400 x 1120 |

| Dhumucda xaashida (mm) | 2-10mm |

Tirada Magaca ee la qeexay

- Matoorka Weyn (CDQC) 40KW 1

- Rullaluistemka Quudinta 0.1KW 1

- Rullaluistemka Hore 0.1KW 1

- Albaabka dambe (Shiinaha) 0.12KW 1/30 1

- Dhaqaaqidda Quudinta (Taiwan) 0.75KW 1/71 2

- Bezel Bidix iyo Midig (Shiinaha) 0.25KW 1/29 2

- Taageerayaasha (Shiinaha) 5.5KW 2

Unugga Daabacaha

- Hagaajinta Roogga Cinjirka ah (Taiwan) 0.4KW 1

- Lift Anilox (Taiwan) 0.2KW 1

- Hawlgalka Anilox (Taiwan) 0.4KW 1

- Dhaqaaqa Cutubka (Taiwan) 0.4KW 1

- Hawlgalka Roogga Cinjirka ah (Taiwan) 0.75KW 1

- Isbeddelka Wajiga (Taiwan) 0.37KW 1/20 1

- Miiska Wiishka (Taiwan) 0.37KW 1/30 1

- Taayirada (Taiwan) 0.37KW 1/50 1

- Taageerayaasha (Shiinaha) 5.5KW 1

Cutubka Slotter

- Isbeddelka Wajiga (Shiinaha) 0.37KW 1/20 2

- Saxanka Tilmaamaha ee Slotted (Shiinaha) 0.55KW 4

- Dhaqaaq Matoorka (Taiwan) 0.4KW 1

- Rullaluistemka Gudbiyaha 0.1KW 2

Cutubka Maqaarka Die

- Qaadista Qalabka (Taiwan) 0.2KW 1

- Qashinka Jaritaanka ee Dhirta (Taiwan) 0.4KW 1

- Isbeddelka Wajiga (Taiwan) 0.37KW 1/20 1

- Taayirada oo leh (Taiwan) 0.37KW 1/50 1

- Gooryaanka Goynta (Shiinaha) 1/100 1

- Rullaluistemka Qaadaha (Taiwan) 0.1KW 1

Cutubka Gaadiidka

- Matoorka ugu weyn (Siemens) 0.75KW 1

- Matoorka Dhinaca (Taiwan) 0.4KW 4

- Pick Arm (Taiwan) 0.4KW 2

- Hoos u dhig oo ka saar matoorka (Taiwan) 0.4KW 2

Cutubka Laablaaban

- Matoorka Giraangiraha Dheecaanka ah (Taiwan) 0.4KW 1

- Dhaqaaqidda xabagta (Taiwan) 0.4KW 1

- Marawaxad Nuugis (Shiinaha) 2.2KW 4

- Taageere Warqad ah (Shiinaha) 3KW 1

- Matoorka Khadka (Shiinaha) 0.4KW 2

- Hoos u dhig oo ka saar matoorka (Taiwan) 1.5KW 2

- Matoorka Xakameynaya (Taiwan) 37KW 2

- Matoorka Farqiga Gudbinta 0.37KW 1

Cutubka Soo Bixinta

- Matoorka Gudbinta Geerarka (Taiwan) 0.75KW 2

- Matoorka Wareejinta Warqadda (Taiwan) 1.5KW 2

- Baffle-ka dambe (Taiwan) 0.55KW 1

- Miiska Soo-dhoweynta (Taiwan) 0.37KW 1

- Baffle-ka dambe (Taiwan) 0.55KW 1

- Miiska Soo-dhoweynta (Taiwan) 0.37KW 1

- Matoorka Gawaarida Riixa (Taiwan) 0.37KW 2

- Matoorka Adeegga Warqadda (Japan) 3KW 1

- Adeegga Warqadda Taageerada 5KW 2

Sharaxaadda Kale

Tirada Asalka Magaca

- NSK, C&U Dhammaan

- Servo Lead Edge Feeder Japan (Omron) Dhammaan

- Dhoobada Anilox Roller Haili, GuangTai All

- Contactor AC, Relay Kulaylka Siemens Dhammaan

- PLC Japan (Omron) Dhammaan

- Encoder Talyaani (ELTRA) Dhammaan

- Shaashadda Taabashada Iswidhan (Beijer) Dhammaan

- Giraanta Xidhiidhka Bilaashka ah ee Shiinaha Dhammaan

- Bamka khad Shiinaha Dhammaan

- Inverter Japan (Yaskawa) Dhammaan

- Solenoid Valve Taiwan (Airtac) Dhammaan

- Mindi Taiwan (Jeefeng) Dhammaan

- Anvil Cover Taiwan (Maxdura) Dhammaan