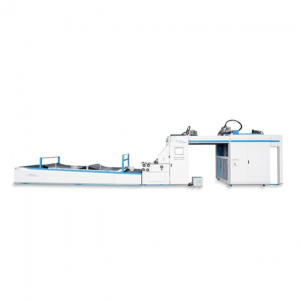

Mashiinka Laminating-ka ee xawaaraha sare leh ee EUFMPro Automatic

Laminator-ka biibiilaha taxanaha EUFM wuxuu ku yimaadaa saddex cabbir oo xaashi ah.

1500*1500MM 1700*1700MM 1900*1900MM

Shaqada:

Warqadda waxaa lagu dahaadhi karaa warqad si loo kordhiyo xoogga iyo dhumucda agabka ama saamaynta gaarka ah. Ka dib jarista, waxaa loo isticmaali karaa sanduuqyada baakadaha, boodhadhka iyo ujeedooyin kale.

Qaab-dhismeedka:

Quudiyaha xaashida sare: Waxay ka soo diri kartaa raso warqad ah oo 120-800gsm ah kor.

Quudiyaha xaashida hoose: Waxay ka soo diri kartaa 0.5 ~ 10mm sagxad/warqad hoose.

Habka dhejiska: Biyaha dhejiska ah waxaa lagu dhejin karaa warqadda la quudiyay. Duubka dhejiska ah waa bir aan miridh lahayn.

Qaab-dhismeedka Kala-hagaajinta - Waxay ku habboon tahay labada warqadood iyadoo loo eegayo dulqaadka la dejiyay.

Qalabka Cadaadiska: Wuxuu riixaa warqadda ku lifaaqan wuxuuna geeyaa qaybta keenista.

Qaababka taxanahan ee alaabada waxaa hal mar lagu farsameeyaa xarun farsamayn oo baaxad weyn leh, taas oo hubinaysa saxnaanta saldhig kasta waxayna hubinaysaa hawlgal xasilloon oo qalabka ah.

Mabaadi'da:

Xaashida sare waxaa soo dira quudiyaha sare waxaana loo diraa qalabka bilowga ee qalabka meelaynta. Kadib xaashida hoose ayaa la diraa; ka dib marka warqadda hoose lagu dahaadho xabag, warqadda sare iyo warqadda hoose waxaa si isku mid ah loogu gudbiyaa warqadda dareemeyaal isku dhafan labada dhinac, ka dib marka la ogaado, kontarooluhu wuxuu xisaabiyaa qiimaha qaladka ee xaashida sare iyo tan hoose, qalabka magdhowga servo ee labada dhinac ee warqadda wuxuu warqadda u hagaajiyaa boos go'an oo loogu talagalay isku-xidhka, ka dibna wuxuu cadaadiyaa gudbinta. Mashiinku wuxuu riixaa warqadda wuxuuna u gudbiyaa mashiinka keenista si uu u soo ururiyo badeecada dhammaatay.

Qalabka lagu dabaqi karo dahaarka:

Warqad koollo ah --- 120 ~ 800g/m warqad khafiif ah, kartoon.

Warqad hoose- ...

Koolada - resin, iwm., qiimaha PH ee u dhexeeya 6 ~ 8, ayaa lagu dabaqi karaa koolada.

Astaamaha qaab-dhismeedka:

Qaadashada nidaamka xakamaynta gudbinta ee ugu horreeya adduunka, cabbirka warqadda la geliyo iyo nidaamka ayaa si otomaatig ah u hagaajin doona.

Laminating-ka xawaaraha sare leh ee kombiyuutarka lagu sameeyay, ilaa 20,000 oo xabbo saacaddii.

Madaxa saadka hawada ee nooca durdurka ah, oo leh afar qaybood oo ah afka hore iyo afar qaybood oo ah afka nuugista.

Feed Block wuxuu qaataa kartoon yar oo is dulsaaran, kaas oo warqadda ku dhejin kara baakadda, wuxuuna ku rakibi karaa qalab hore u rakibay oo raad-raac ah.

Adeegso dhowr indhood oo koronto ah si aad u ogaato booska hore ee xariiqda hoose, oo samee matoorka servo ee labada dhinac ee warqadda wejiga si madax-bannaan u wareega si uu u magdhabo iswaafajinta warqadda sare iyo tan hoose, taas oo sax ah oo siman.

Nidaamka xakamaynta elektaroonigga ah ee shaqada oo buuxa, iyadoo la adeegsanayo is-dhexgalka mashiinka aadanaha iyo bandhigga moodeelka barnaamijka PLC, ayaa si toos ah u ogaan kara xaaladaha hawlgalka iyo diiwaannada shaqada.

Nidaamka buuxinta koolada otomaatiga ah wuxuu si toos ah u magdhabi karaa koolada lumay wuxuuna la shaqeyn karaa dib u warshadaynta koolada.

Mashiinka laminating-ka xawaaraha sare leh ee EUFM waxaa lagu xiri karaa stacker flip flop ah oo otomaatig ah si loo badbaadiyo shaqada.

| Moodel | EUFM1500PRO | EUFM1700PRO | EUFM1900PRO |

| Cabbirka ugu badan | 1500 * 1500mm | 1700*1700mm | 1900 * 1900mm |

| Cabbirka ugu yar | 360 * 380mm | 360 * 400mm | 500 * 500mm |

| Warqad | 120-800g | 120-800g | 120-800g |

| Warqadda hoose | ≤10mm loox jiingado ah oo ABCDEF ah ≥300gsm kartoon | ≤10mm loox jiingado ah oo ABCDEF ah ≥300gsm kartoon | ≤10mm ABCDEF Loox jiingado ah oo ka badan 300gsm kartoon |

| Xawaaraha ugu badan ee laminating | 180m/daqiiqo | 180m/daqiiqo | 180m/daqiiqo |

| Awood | 22kw | 25kw | 270KW |

| Saxnaanta usha | ±1mm | ±1mm | ±1mm |

1. QIIMEYNTA WARQADDA HOOS KU XUSAN

Adeegso nidaamka xakamaynta korontada ee matoorka Servo ee la soo dhoofiyay, oo leh suunka nuugista ee NITTA ee Japan si aad u samayso beddelaha awoodda nuugista, iyo suunka lagu nadiifiyo biyo-rogidda.

Tiknoolajiyada shatiga leh si loo hubiyo in qalabka iyo kartoonku si habsami leh u shaqeeyaan.

2. Habka quudinta xaashida ugu sareysa

Labada nooc ee kor u qaadista warqadda iyo quudinta ee quudinta xawaaraha sare leh ee otomaatiga ah ayaa si xor ah loogu hagaajin karaa si loogu waafajiyo warqad khafiif ah iyo mid qaro weyn labadaba. Iyada oo la socota bamka Becker, hubi in warqadda quudinta sare ay si dhakhso leh oo siman u shaqeyso.

3. NIDAAMKA KORONTADA

Naqshadeeyay oo qaatay koontaroolka dhaqdhaqaaqa oo ay weheliso nidaamka Yaskawa Servo iyo inverter, Siemens PLC si loo hubiyo in mashiinku ku shaqeeyo xawaaraha ugu badan iyo saxnaanta sida waxqabadka sare iyo xasilloonida socodsiinta. Adigoo isticmaalaya interface-ka mashiinka aadanaha iyo isku-darka PLC, soo bandhig dhammaan macluumaadka shaashadda. Shaqada xusuusta dalbashada, hal guji si aad u wareejiso amarkii hore, ku habboon oo dhakhso badan.

4. QAYBTA KA HOR JIRA

Nidaamka hore loo sii diyaariyey oo leh shaqo hore loo sii diyaariyey ayaa loo dejin karaa cabbir warqad ah iyada oo loo marayo shaashadda taabashada waxaana si toos ah loogu hagi karaa si loo yareeyo waqtiga dejinta si hufan.

5. Nidaamka Gudbinta

Albaabada suunka isku-dhafan oo ay weheliso SKF oo ah gudbinta ugu weyn ayaa la isticmaalaa si loo hubiyo xasilloonida. Labada duub ee cadaadiska, duubka yareeya iyo qiimaha xabagta waxaa si fudud loogu hagaajin karaa gacan iyadoo la adeegsanayo qalab farsamaysan.

6. NIDAAMKA BOOS-GELINTA

Sawir-qaadaha oo ay weheliso xakamaynta dhaqdhaqaaqa iyo nidaamka Yaskawa Servo waxay hubiyaan saxnaanta jihada warqadda sare iyo tan hoose. Duubka xabagta birta ah oo aan miridh lahayn oo leh shiidi anilox fiican si loo hubiyo dahaarka xabagta oo siman xitaa tirada xabagta ugu yar.

7.NIDAAMKA XABBO

Roolada anilox ee dhexroorkoodu yahay 160mm oo aad u weyn oo leh duub riixitaan ah oo 150mm ah si ay mashiinka uga dhigto mid si dhakhso leh u shaqeeya iyadoo la isticmaalayo buufin koollo yar iyo duubista riixitaanka Teflon waxay si hufan u yareyn kartaa nadiifinta usha koollada. Qiimaha dahaarka koollada waxaa lagu dejin karaa shaashadda taabashada waxaana si sax ah u xakameyn kara matoorka servo.

8. SHAASHADA TAABASHADA IYO JIHEYSIGA TOOSKA AH

Qaabka warqadda waxaa lagu dejin karaa 15 inji oo Taabasho ah waxaana si toos ah loogu hagi karaa matoorka inverter-ka si loo yareeyo waqtiga dejinta. Jihaynta otomaatiga ah waxaa lagu dabaqayaa cutubka ka horreeya tuulmada, cutubka quudinta sare, cutubka quudinta hoose iyo cutubka meelaynta. Badhanka taxanaha Eaton M22 wuxuu hubiyaa waqti dheer oo shaqada ah iyo quruxda mashiinka.

9. HAGGABINTA DHULKA

Farqiga wareega si toos ah ayaa loo hagaajin karaa iyadoo loo eegayo qiimaha la ogaaday.

10. GUDIYE

Qalabka xamuulka qaada ee kor loo qaaday ayaa sahlaya hawlwadeenka inuu soo dejiyo warqadda. Qalabka xamuulka qaada ee dheer oo ay weheliso suunka cadaadiska si shaqada dahaaran ay si dhakhso ah u qallajiso.

11. NIDAAMKA SUMBISTA TOOS AH

Bamka saliidaynta otomaatiga ah ee dhammaan walxaha ugu muhiimsan waxay hubisaa in mashiinka uu adkeysi xoog leh yeesho xitaa xaalad shaqo oo culus.

1. NIDAAMKA QIIMEYNTA XIDHIIDHKA EE HOGAAMIYAHA AH

Cidhifka rasaasta wuxuu hubiyaa in looxa jiingadaha qaro weyn sida 5 ama 7 lakab uu si habsami leh u shaqeeyo xitaa marka uu aad u bogsanayo.

2. Quudiyaha SERVO ee aan shaft lahayn

Quudiyaha servo ee aan shaftless-ka lahayn ayaa loo isticmaalaa xaashi dheer oo dheeraad ah oo dhaqdhaqaaq dabacsan leh.

3. Ilaalada Badbaadada Dheeraadka ah iyo Gudbinta Badbaadada

Dabool dheeraad ah oo xiran oo ku wareegsan mashiinka si loo helo caawimo dheeraad ah oo badbaado. Qalabka dib u celinta amniga si loo hubiyo in albaabka la furo iyo E-stop-ku si joogto ah u shaqeeyaan.

| Taxane | Qayb | Waddan | Summada |

| 1 | matoorka ugu weyn | Jarmalka | Siemens |

| 2 | shaashadda taabashada | Taiwan | WEINVIEW |

| 3 | matoorka servo | Jabaan | Yaskawa |

| 4 | Silsilad hage toosan iyo tareenka hagaha | Taiwan | HIWIN |

| 5 | Yaraynta xawaaraha warqadda | Jarmalka | Siemens |

| 6 | Solenoid rogidda | Jabaan | SMC |

| 7 | Riix matoorka hore iyo kan dambe | Taiwan | Shanteng |

| 8 | Matoorka cadaadiska | Jarmalka | Siemens |

| 9 | Matoorka wax-ka-beddelka ballaca mishiinka ugu weyn | Taiwan | CPG |

| 10 | Mashiinka ballaca quudinta | Taiwan | CPG |

| 11 | matoorka quudinta | Taiwan | Lide |

| 12 | Bamka cadaadiska faakuumka | Jarmalka | Becker |

| 13 | Silsilad | Jabaan | TSUBAKI |

| 14 | Relay | Jabaan | Omroon |

| 15 | badhanka elektaroonigga ah ee optoelectronic | Taiwan | FOTEK |

| 16 | Relay-adag | Taiwan | FOTEK |

| 17 | furayaasha isku-dhafka ah | Jabaan | Omroon |

| 18 | Relay heerka biyaha | Taiwan | FOTEK |

| 19 | Xiriiriyaha | Faransiiska | Schneider |

| 20 | PLC | Jarmalka | Siemens |

| 21 | Darawalada Servo | Jabaan | Yaskawa |

| 22 | Beddelaha soo noqnoqda | Jabaan | Yaskawa |

| 23 | Potentiometer | Jabaan | TOCOS |

| 24 | Encoder-ka | Jabaan | Omroon |

| 25 | Badhan | Faransiiska | Schneider |

| 26 | Iska-caabinta biriiga | Taiwan | TAYEE |

| 27 | Gudbinta Xaaladda Adag | Taiwan | FOTEK |

| 28 | Beddelaha hawada | Faransiiska | Schneider |

| 29 | Qalabka Heerkulka | Faransiiska | Schneider |

| 30 | Nidaamka korontada DC | Taiwan | Mingwei |