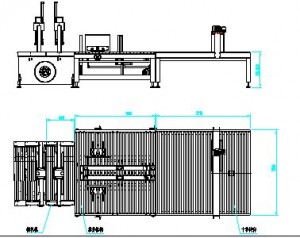

Kuleyliyaha Faylka Tooska ah iyo Tolmada sanduuqa jiingadaha (JHXDX-2600B2-2)

| Moodel | JHXDX-2600B2-2 |

| Aagga Rakibaadda | 16000 * 4200mm |

| Awood Guud | 28.5Kw |

| Xawaaraha ugu Badan ee Tolmada | 1050 Ciddiyaha/daqiiqaddii |

| Dhumucda Xaashida | A, B, C, AB |

| Heerka garoonka | 40-500mm |

| Lambarka Ciddiyaha | 1-40 (ciddiyaha) |

| Cabbirka Siliggu | Lambarka.17(2.0*0.7mm), Lambarka.18(1.81*0.71mm) |

Marka la dhejiyo

| Moodel | JHXDX-2600B2-2 | |

|

| Ugu badnaan (mm) | Ugu yaraan (mm) |

| A | 880 | 200 |

| B | 900 | 100 |

| C | 880 | 200 |

| D | 900 | 100 |

| E | 2500 | 680 |

| F | 900 | 300 |

| G | 35-40 | |

Goorta la tolayo

| Moodel | JHXDX-2600B2-2 | |

|

| Ugu badnaan (mm) | Ugu yaraan (mm) |

| A | 650 | 230 |

| B | 550 | 200 |

| C | 650 | 230 |

| D | 550 | 200 |

| E | 2400 | 860 |

| F | 900 | 350 |

| G | 35-40 | |

a)Astaamaha Muhiimka ah

●Qayb gaar ah oo kala soocid xaashi iyo diiwaangelin ah oo ka takhalusi karta kalluunka

ifafaale dabada ah oo wax ku ool ah.

● Ku dhejinta, tolida, koolada + tolida waxaa lagu hagaajin karaa hal riix oo aad u badan

ku habboon hawlgalka

●Mindi-jarista tolmada iyo meesha ciddiyaha lagu dhejiyo waxay qaadataa dahaar adag oo dibadda laga keeno taasoo hubinaysa

cimriga shaqada oo dheer

●Hawsha kaydinta dalabka waxay ku kaydin kartaa cabbirka kartoonka shaashadda taabashada, mashiinku si toos ah ayuu u hagaajin doonaa marka hawlwadeenku doorto dalab la keydiyay.

b)Astaamaha ugu Muhiimsan

● Naqshadda shatiga ee mindi laalaaban karo oo 90° ah ayaa ka dhigi karta kartoonka mid si sax ah u laalaaban kara.

● Nooca Yaskawa ee la soo dejiyo ee matoorada afar-servo leh oo leh astaamo sax ah, waxay yareyn kartaa aaladaha gudbinta waxayna ka dhigaysaa mid aan dhib lahayn.

● Isticmaalka matoorka si loo hagaajiyo suunka isku-dhafan, si fudud ayaa loo shaqeeyaa loona yareeyaa waqtiga isbeddelka.

● Madaxa tolida qaabka loo lulo, suunka isku-dhafan iyo madaxa tolida oo si isku-dhafan u dhaqdhaqaaqa, waxay gaari kartaa tolida iyadoo la dhaqaajinayo xaashida, xawaare degdeg ah iyo hufnaan sare.

Cutubka Quudinta:

a) Qaado suunka faakiyuumka caagga ah ee tayo sare leh, kaydka iyo gelinta otomaatiga ah si loo hubiyo waxtarka quudinta.

b) Naqshad gaar ah ayaa ka dhigaysa hagaajinta mid fudud, dhaqso badan oo sax ah. Nidaaminta dhinaca pneumatic, baffle-ka quudinta warqadda iyo suunka ayaa si gaar ah loo shaqeeyaa, taas oo ka dhigaysa isbeddelka dalabka mid fudud.

Giraangiraha qalloocan

Waxaa jira giraangir kor u kaca meesha lagu dhejiyo, saameynta laablaabkuna way ka fiican tahay.

Cutubka Daboolka:

a) Ballaca dhejisku waa 25mm/35 mm-ku-dhejin dhinaca hoose.

b) Sanduuqa xabagta waxaa loo dhaqaajin karaa bidix ama midig iyadoo loo eegayo shuruudaha looxa jiingadda.

c) Qadarka dhejiska waa la hagaajin karaa.

d) Sanduuqa xabagta waxa laga sameeyay bir aan miridh lahayn - waa mid aad u weyn oo si fudud loo nadiifin karo.

e) Nidaamka xakamaynta korontada ayaa ka dhigaya tolida ciddiyaha mid sax ah.

f) Qalabka quudinta ciddiyaha oo otomaatig ah, afar dareemayaal oo ogaanaya jabitaanka ciddiyaha oo yaraaday.

Rullaluistemka cadaadiska

Toddobada wareeg ee cadaadiska laga bilaabo kuwa waaweyn ilaa kuwa yaryar, ma fududa in la burburiyo warqadda oo la hubiyo saameynta laalaabka wanaagsan.

Cutubka Laablaaban

a) Waxay isticmaashaa suunka is jiidjiidka sare. Xawaaraha laablaabashada waxaa xakameeya qalabka wax lagu beddelo ee soo noqnoqda kaas oo si gaar ah loo xakamayn karo loona waafajin karo matoorka ugu weyn.

b) Matoorka oo loogu talagalay hagaajinta isbeddelka dalabka - si dhakhso leh oo ku habboon.

c) Dib-u-habaynta duubista, mindiyaha dib-u-habaynta, duubista dhinaca iyo saxanka laalaaban karo ayaa si wax ku ool ah u baabi'in kara dabada kalluunka. Mindida dib-u-habaynta waxay qaadataa naqshad iyo qaab-dhismeed cusub taasoo ka dhigaysa kartoonka mid toosan oo qumman.

d) Qaybaha xoojinta sare waxay qaataan qalabka birta lagu dhejiyo ee laydhka iyo qalabka qufulka pneumatic-ka, waxay ka dhigaysaa mashiinku inuu si xawli ah ugu shaqeeyo taasoo hubin karta in si sax ah loo laabo.

Rullaluistemka cadaadiska shaandhada

Waxaa jira roogag cadaadis oo toosan oo ku yaal dhabarka laablaabashada bidix iyo midig kuwaas oo gaari kara laablaab 90 darajo ah.

Qaybta Kala-soocidda iyo Diiwaangelinta Warqadaha

a) Naqshadeenna gaarka ah ee cutubka kala duwanaanshaha xawaaraha iyo sheet side laysarka ayaa ku xidhmi kara dhejis kale oo faylal otomaatig ah.

b) Marka la doorto qaabka tolida, waxaa jira laba matoor oo servo ah oo xakameeya ficillada isku-hagaajinta xaashida, nidaamka magdhowga labaad iyo sixitaanka wuxuu baabi'iyaa ifafaalaha dabada kalluunka.

Shaqada Hagaajinta Tooska ah

Dib-u-habaynta iyo qaab-dhismeedka giraangiraha taageerada, xakamaynta korantada iyo wadista matoorka ayaa ka dhigaya hagaajinta mid dhakhso badan oo ku habboon, oo ku habboon loox jiingado ah oo dhumucdiisu kala duwan tahay.

Qaybta sare ee xaashida jiingadda ah u qaado xariiqda salka si aad u hesho meel sax ah oo aad si weyn u yareyso dhibaatada dabada kalluunka.

Mootada iyo encoder-ku waxay ka dhigayaan hagaajinta mid fudud oo ku habboon, hawlwadeenku wuxuu keydin karaa xogta xaashida iyada oo loo marayo shaashadda taabashada.

Cutubka Tolmada

1. Waxay qaadataa wadista suunka isku-dhafan, nidaamka xakamaynta PLC, hagaajinta shaashadda taabashada, ku habboon, dhakhso badan oo sax ah.

2. Madaxa tolida qaabka lulid oo leh astaamo ah isticmaalka awoodda oo yar, xawaare dhakhso badan iyo xasillooni sare ayaa si wax ku ool ah u horumarin kara tayada badeecada.

3. Hal badhan ayaa xakameeya qaabka isku dhejinta iyo is-weydaarsiga qaabka tolida, dhammaan hagaajinta waxaa xakameeya matoorka korontada.

4. Madaxa tolida iyo madaxa kor iyo hoos waxaa maamula matoorada korontada. Mindida la jaray waxay qaadataa walxo carbide ah oo sibidh ah, cimri dheer.

5. Qaabka ciddiyaha waa la hagaajin karaa sida loogu baahan yahay xaashida.

Cutubka Is-ururinta iyo Tirinta

a) Saxanka Kala-baxa wuxuu kaa caawin karaa yareynta ifafaalaha dabada kalluunka marka la dhejinayo.

b) Lambarka tuulmada waxaa lagu dejin karaa 10, 15, 20 iyo 25.

Qaab-dhismeed farsamo oo cilmiyeysan oo macquul ah, walxo koronto oo tayo leh oo la isku halleyn karo ayaa mashiinka ka dhigaya mid aan dhibaato lahayn. Matoorka servo ee nooca Yasakawa wuxuu hubin karaa cimriga.

a)Qaybta Korontada:

| Magaca | Summada | Faahfaahinta | Moodel | Tirada |

| Beddelaha soo noqnoqda | Biilasha |

| MD300 | 1 |

| Awood | Taiwan Macno ahaan Wanaagsan | S-150-24 | NES-150-24 | 1 |

| Xiriiriyaha | Faransiiska Schneider | LC1-D0910M5C | LCDE0910M5N | 5 |

| Badhanka xakamaynta | Shanghai Tianyi | Badhan cagaaran | LA42P-10 | 13 |

| Badhan cas | LA42PD-01 | 1 | ||

| Nalalka cagaaran | LA42PD-10/DC 24V | 4 | ||

| Nalalka cas | LA42PD-01/DC 24V | 4 | ||

| Laambad jaalle ah | LA42PD-20/DC 24V | 1 | ||

| Badhanka xakamaynta | Fuji |

| LA42J-01 | 1 |

| Beddelka sawirka korontada | OPTEX |

| BTS-10N | 1 |

| Beddelaha hawada | Delixi | DZ47 | E3F3-D11 | 1 |

| Shaashadda taabashada | Hitech | 10 inji | PWS5610T-SB | 1 |

| PLC | Biilasha |

|

|

|

b)Qaybaha Farsamada ee ugu Muhiimsan:

|

| Magaca | Summada | Tirada |

| 1 | Suunka quudinta (A) | Bailite | 6 |

| 2 | Suunka qaabilaadda (C) | Forbo-siegling | 19 |

| 3 | Suunka gudbiyaha (B) | Forbo-siegling | 13 |

| 4 | Marwaxad hawada | Hengshui (Shatiga) | 1 |

| 5 | Matoorka ugu weyn | Simens (dhinaca) | 1 |

| 6 | Matoorka Geerka | Zhejiang | 6 |

| 7 | Matoorka Adeegga | Yaskawa | 4 |

-Sample-300x260.jpg)