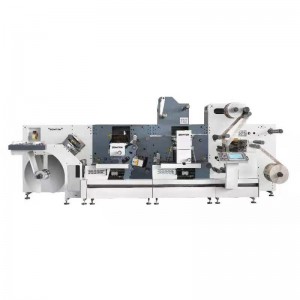

Mesin Pemotong Mati Amben Datar Dragon 320

| Model | NAGA-320 |

| Mkacepetan kapak | 120M/MENIT |

| Jembar kertas efektif maksimal | 330MM |

| Skacepetan sablon ilk | 60-100 kali/menit |

| Akurasi pemotongan perekat Akurasi pemotongan IML | ±0.15mm ±0.25mm |

| Registrasi | Sensor |

| Diameter foil panas maksimal | 300mm |

| Arah pakan foil panas | 0 ijo/90 ijo |

| Pangaturan lompatan foil | Dhukungan dening servo |

| Akurasi register foil | ±0.15mm |

| Rentang panas | 0-200 dgree |

| Area flekso semi rotary 144 Z | 400mm * 320mm |

| Area pemotongan mati semi rotary 144Z | 400*320 mm |

| Pasokan udara | 0.4-0.6pa |

| Dimensi | 11275*1510*1820MM |

| bobot | 8000 kg |

| Servsupir | Panasonic Jepang (kalebu unwinding / feeding / rewinding / flexo / die cutting) total 10 pcs |

| Sistem kontrol | Trio Inggris |

| PLC (Plank) | Panasonic Jepang |

| Transduser | Panasonic Jepang |

| Kontaktor | Schneider Prancis |

| Saklar udara | Schneider Prancis |

| Nilai | Schneider Prancis |

| Layar tutul | Pingtong Taiwan |

| Jaring pandhuan | BST Jerman |

| Tombol | Schneider Prancis |

| Ora. | Produk |

| 1 | Lini produksi konversi DRAGON -320 kalebu: Konfigurasi dhasar: Unit hot stamping sing ora kaku + amben rata + Rewinder |

| 2 | Unit flekso semi putar |

| 3 | Unit layar sutra |

| 4 | Unit flekso semi putar |

| 5 | Unit foil panas amben datar |

| 6 | Unit pemotong mati amben datar |

| 7 | Unit pemotong mati semi putar |