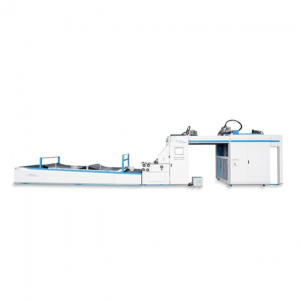

Injin Laminating na Busawa Mai Sauri na EUFMPro ta atomatik

Laminator ɗin busa ƙaho na EUFM yana zuwa a girma uku na takardu.

1500*1500MM 1700*1700MM 1900*1900MM

Aiki:

Ana iya yi wa takardar laminate da takarda don ƙara ƙarfi da kauri na kayan ko tasirin musamman. Bayan yankewa, ana iya amfani da shi don akwatunan marufi, allunan talla da sauran dalilai.

Tsarin:

Mai Ciyar da Takarda ta Sama: Yana iya aika tarin takarda mai nauyin 120-800gsm daga sama.

Mai ciyar da takardar ƙasa: Zai iya aika 0.5 ~ 10mm Corrugated/paperboard daga ƙasa.

Tsarin mannewa: Ana iya shafa ruwan manne a kan takardar da aka ciyar. Naɗin manne na bakin ƙarfe ne.

Tsarin daidaitawa - Ya dace da takardu biyu bisa ga juriyar da aka saita.

Mai Matsi: Yana danna takardar da aka haɗa sannan ya kai ta sashin isar da kaya.

Ana sarrafa firam ɗin wannan jerin samfuran a lokaci guda ta hanyar babban cibiyar injina, wanda ke tabbatar da daidaiton kowane tasha kuma yana tabbatar da ingantaccen aikin kayan aiki

Ka'idoji:

Ana aika takardar saman ta hanyar mai ciyarwa ta sama sannan a aika ta zuwa na'urar gano wuri na na'urar sanyaya wuri. Sannan a aika takardar ƙasa; bayan an shafa takardar ƙasa da manne, ana aika takardar sama da takardar ƙasa zuwa takardar masu gano wuri a ɓangarorin biyu, bayan an gano, mai sarrafawa yana ƙididdige ƙimar kuskuren takardar sama da ta ƙasa, na'urar diyya ta servo a ɓangarorin biyu na takardar tana daidaita takardar zuwa matsayin da aka riga aka tsara don haɗawa, sannan ta matsa jigilar. Injin yana danna takardar ya kai ta injin isarwa don tattara samfurin da aka gama.

Kayan da ake amfani da su don laminating:

Takardar liƙa --- Takarda mai siriri 120 ~ 800g/m, kwali.

Takarda ta ƙasa- ...

Ana iya amfani da manne - resin, da sauransu, ƙimar PH tsakanin 6 zuwa 8, a kan manne.

Siffofin gini:

Amfani da tsarin sarrafa watsawa mafi girma a duniya, girman takardar shigarwa da tsarin zai daidaita ta atomatik.

Laminating mai saurin kwamfuta, har zuwa guda 20,000 a kowace awa.

Kan samar da iska mai kama da ruwa, tare da saitin bututun gaba guda huɗu da saitin bututun tsotsa guda huɗu.

Feed Block yana amfani da kwali mai ƙarancin tari, wanda zai iya dacewa da takardar a kan fakitin, kuma zai iya shigar da mai tsarawa wanda aka taimaka wa hanya.

Yi amfani da saitin idanu masu amfani da wutar lantarki da yawa don gano matsayin gaba na layin ƙasa, kuma sanya injin servo a ɓangarorin biyu na takardar fuska ya juya daban-daban don daidaita daidaiton takarda na sama da ƙasa, wanda yake daidai kuma santsi.

Tsarin sarrafa lantarki mai cikakken aiki, ta amfani da hanyar sadarwa ta injin ɗan adam da kuma nunin samfurin shirin PLC, zai iya gano yanayin aiki da bayanan aiki ta atomatik.

Tsarin sake cika manne ta atomatik zai iya ramawa ta atomatik idan manne ya ɓace kuma ya haɗa kai da sake amfani da manne.

Ana iya haɗa injin laminating mai sauri na EUFM tare da na'urar jujjuyawa ta atomatik don adana aiki.

| Samfuri | EUFM1500PRO | EUFM1700PRO | EUFM1900PRO |

| Matsakaicin girma | 1500*1500mm | 1700*1700mm | 1900*1900mm |

| Ƙaramin girman | 360*380mm | 360*400mm | 500*500mm |

| Takarda | 120-800g | 120-800g | 120-800g |

| Takarda ta ƙasa | ≤10mm allon corrugated ABCDEF ≥300gsm kwali | ≤10mm allon corrugated ABCDEF ≥300gsm kwali | ≤10mm ABCDEF allon da aka yi da corrugated ≥300gsm kwali |

| Matsakaicin saurin laminating | 180m/min | 180m/min | 180m/min |

| Ƙarfi | 22kw | 25kw | 270KW |

| Daidaiton sanda | ±1mm | ±1mm | ±1mm |

1. CIYAR DA TAKARDAR ASALIN

Yi amfani da tsarin sarrafa wutar lantarki na injin Servo da aka shigo da shi, tare da bel ɗin tsotsa na NITTA na Japan don yin inverter na ƙarfin tsotsa, da kuma bel ɗin da aka tsaftace ta hanyar na'urar birgima ta ruwa.

Fasaha mai lasisi don tabbatar da cewa corrugate da kwali suna fita cikin sauƙi kuma cikin sauƙi.

2. Tsarin ciyar da takardar sama

Ana iya daidaita bututun ɗaga takarda da ciyarwa na mai ciyarwa mai sauri ta atomatik don daidaitawa da takarda mai siriri da kauri. Tare da famfon Becker, tabbatar da cewa takardar ciyarwa ta sama tana aiki da sauri da kuma lanƙwasa.

3. TSARIN WUTAR LANTARKI

An tsara kuma an rungumi na'urar sarrafa motsi tare da tsarin Yaskawa Servo da inverter, Siemens PLC don tabbatar da cewa injin yana aiki a mafi girman gudu da daidaito a matsayin babban aiki da kwanciyar hankali na aiki. Ta amfani da hanyar haɗin injin mutum da haɗin PLC, nuna duk bayanan da ke kan allon. Aikin ƙwaƙwalwar oda, dannawa ɗaya don canja wurin oda na baya, mai sauƙi da sauri.

4. KASHIN KAFIN TARKO

Tsarin pre-taro tare da aikin da aka saita za a iya saita shi azaman girman takarda ta hanyar allon taɓawa kuma a daidaita shi ta atomatik don rage lokacin saitawa yadda ya kamata.

5. Tsarin Watsawa

Ana amfani da bel ɗin daidaitawa na ƙofofi tare da bearing na SKF a matsayin babban watsawa don tabbatar da kwanciyar hankali. Ana iya daidaita na'urorin juyawar matsin lamba, na'urar juyawa da ƙimar manne cikin sauƙi ta hanyar riƙewa tare da na'urar ɓoyewa ta injiniya.

6. Tsarin Matsayi

Photocell tare da sarrafa motsi da tsarin Yaskawa Servo suna tabbatar da daidaiton daidaiton takarda ta sama da ƙasa. Na'urar naɗa manne mai bakin ƙarfe tare da niƙa anilox mai kyau don tabbatar da daidaiton murfin manne ko da a ƙaramin adadin manne.

7.TSARIN MANTUWA

Babban abin nadi mai girman 160mm mai siffar anilox tare da abin nadi mai matsewa 150mm don sa injin yayi aiki da sauri tare da ƙarancin feshi na manne da abin nadi na manne na Teflon na iya rage tsaftace sandar manne yadda ya kamata. Ana iya saita ƙimar murfin manne akan allon taɓawa kuma a sarrafa shi daidai ta hanyar injin servo.

8. Allon taɓawa da kuma daidaitawa ta atomatik

Ana iya saita tsarin takarda ta hanyar Na'urar Kula da Taɓawa mai inci 15 kuma a mayar da shi ta hanyar injin inverter ta atomatik don rage lokacin saitawa. Ana amfani da yanayin atomatik ga na'urar da aka riga aka shirya, na'urar ciyarwa ta sama, na'urar ciyarwa ta ƙasa da na'urar sanyawa. Maɓallin jerin Eaton M22 yana tabbatar da tsawon lokacin aiki da kyawun injin.

9. GYARA KAURIN

Ana iya daidaita gibin na'urar ta atomatik bisa ga ƙimar da aka gano.

10. MAI ƊAUKARWA

Na'urar jigilar kaya mai ɗagawa tana sauƙaƙa wa mai aiki sauke takarda. Na'urar jigilar kaya mai tsayi tare da bel ɗin matsi don sa aikin da aka yi wa laminate ya bushe da sauri.

11. TSARIN MAN SHAFA NA AUTOMATIC

Famfon shafawa na atomatik don duk manyan bearings yana tabbatar da ƙarfin injin ko da a ƙarƙashin yanayin aiki mai nauyi.

1. JAGORAN TSARIN CIYAYYA TA GEFE

Gefen gubar yana tabbatar da cewa allon da aka yi da corrugated kamar yadudduka 5 ko 7 yana aiki cikin sauƙi koda kuwa a ƙarƙashin yanayin warkewa sosai.

2. Mai ciyar da kayan aiki na shaftless

Ana amfani da ciyarwar servo mara shaft don ƙarin dogon takarda a motsi mai sassauƙa.

3. ƘARIN KARIYA DA JUYIN JUYA TSARO

Ƙarin murfin rufewa a kusa da na'urar don ƙarin taimakon tsaro. Motar tsaro don tabbatar da cewa maɓallin ƙofa da E-stop suna aiki akai-akai.

| Jerin Jeri | Sashe | Ƙasa | Alamar kasuwanci |

| 1 | babban injin | Jamus | Siemens |

| 2 | kariyar tabawa | Taiwan | WEINVIEW |

| 3 | injin servo | Japan | Yaskawa |

| 4 | Zane mai jagora mai layi da kuma layin jagora | Taiwan | HIWIN |

| 5 | Mai rage saurin takarda | Jamus | Siemens |

| 6 | Juyawa ta Solenoid | Japan | SMC |

| 7 | Matse injin gaba da baya | Taiwan | Shanteng |

| 8 | Injin latsawa | Jamus | Siemens |

| 9 | Babban injin gyaran faɗin injin | Taiwan | CPG |

| 10 | Ciyar da fadin mota | Taiwan | CPG |

| 11 | Ciyar da injin | Taiwan | Lide |

| 12 | famfon matsin lamba na injin | Jamus | Becker |

| 13 | Sarka | Japan | TSUBAKI |

| 14 | Relay | Japan | Omron |

| 15 | maɓallin lantarki na optoelectronic | Taiwan | FOTEK |

| 16 | Mai watsa shirye-shirye mai ƙarfi | Taiwan | FOTEK |

| 17 | maɓallan haɓakawa | Japan | Omron |

| 18 | na'urar jigilar ruwa matakin ruwa | Taiwan | FOTEK |

| 19 | Mai hulɗa | Faransa | Schneider |

| 20 | Kamfanin PLC | Jamus | Siemens |

| 21 | Direbobin Servo | Japan | Yaskawa |

| 22 | Mai sauya mita | Japan | Yaskawa |

| 23 | Mai auna ƙarfin lantarki | Japan | TOCES |

| 24 | Mai Encoder | Japan | Omron |

| 25 | Maɓalli | Faransa | Schneider |

| 26 | Resistor na birki | Taiwan | TAYEE |

| 27 | Mai watsa shirye-shirye mai ƙarfi | Taiwan | FOTEK |

| 28 | Makullin iska | Faransa | Schneider |

| 29 | Na'urar juyawa ta Thermo | Faransa | Schneider |

| 30 | Tsarin wutar lantarki na DC | Taiwan | Mingwei |